まさにストーンズ!ロレックスのトレンドを生み出す青と緑の文字盤

“All things that are beautiful with color, such as flowers and leaves, or the blue of the sky and the glory of sunset, are fleeting and ever-changing. Only the luster and color of precious stones have remained unchanged from thousands of years ago until now. Thousands of years later, they will be the same”

- [宝石の奇妙な言い伝え]

ジョージ F. クンツ (宝石学者および鉱物学者、1856 ~ 1932 年)

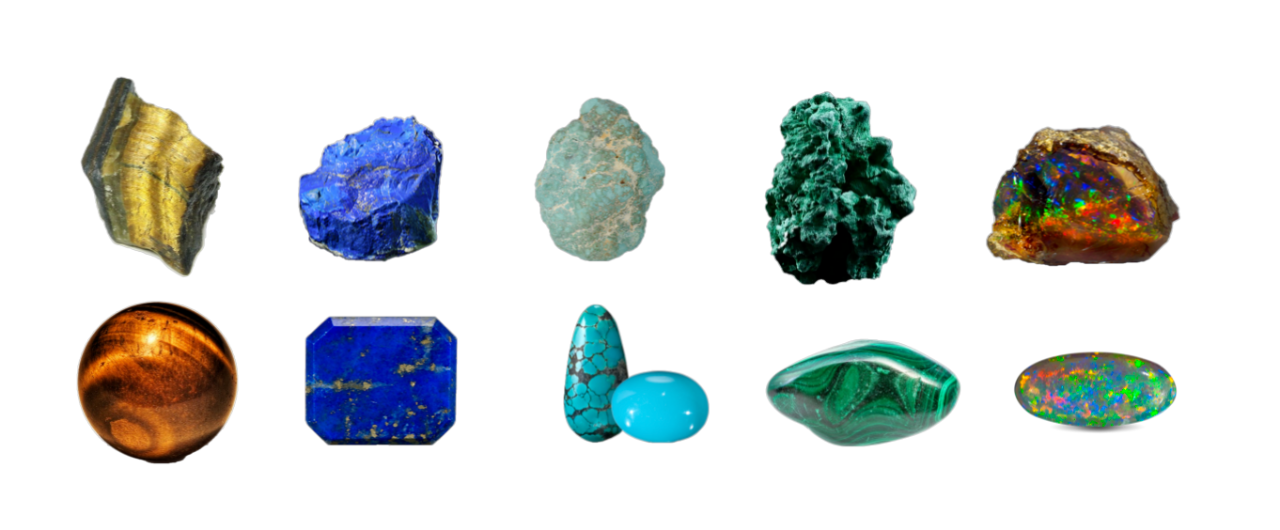

宝石の使用はジュエリーに限定されません。それらは時計製造でも一般的です。ほとんどの宝石は耐久性に優れていることで知られており、その豊かな色と光沢が時計の美しさを高めます。

時計のケースにセットされたり、時計の文字盤の装飾として使用されます。パントンが今年の色を発表するのと同様に、近年、時計業界では、さまざまな時期にさまざまな色が時計の文字盤を支配する傾向があります。

各ブランドはペイントやエナメルなどの技法で色を表現しており、さまざまな素材の宝石を使用して文字盤を作ることも人気のある手法です。

腕時計にとって美しさとは何でしょうか?

私たちはケースのデザイン、文字盤のレイアウト、透明なケースバック、複雑な機能などの要素をすべて小さなスペースの範囲内で考慮し、細部に美しさが宿ります。

The dial, often compared to a “facial expression” for watches, is undoubtedly influenced by its color. As mentioned, when gemstones are crafted into watch dials, the emphasis tends to lean towards considerations of “color coordination.” Therefore, compared to the intrinsic value of the gemstone itself, its color plays a crucial role in expressing the overall aesthetic appeal of the watch and significantly impacts its value.

In the pursuit of enhancing the visual allure of this “face,” brands invest effort into selecting gemstones of appropriate colors.

この記事ではさまざまな種類の貴石を使用していますが、以下では時計の文字盤の作成に一般的に使用される宝石をいくつか紹介します。

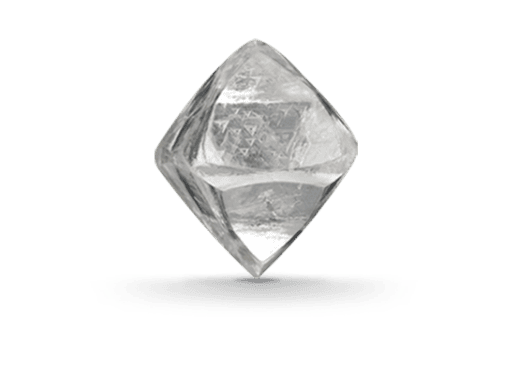

0ダイヤモンド1個

ダイヤモンドは単一元素である炭素原子で構成されている唯一の宝石であり、炭素含有量は 99.95% にも及びます。残りの 0.05% は、基本的な化学構造に属さない微量元素で構成されています。ダイヤモンドのほとんどは 10 億年以上前の古代に形成され、地表から約 160 マイルの地下で高温高圧の条件下でのみ結晶化しました。

無色のダイヤモンドの品質はどのように評価すればよいのでしょうか?カラット(重量)、カラー、クラリティ、カットの4Cに基づいています。 これらの基準によれば、良いダイヤモンドとは、より大きく、より無色で、より透明で、よくカットされたものです。さらに、非常に価値の高い貴重なカラーダイヤモンドもいくつかあります。

ダイヤモンドの歴史は古く、インドでのダイヤモンド取引の記録は紀元前 800 年まで遡ります。今日、ダイヤモンドは世界中で広く普及しています。南アフリカとオーストラリアはダイヤモンドの主要産地です。

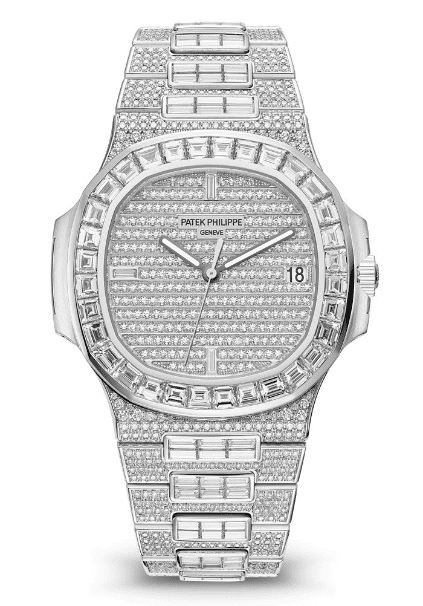

ダイヤモンドは他の宝石にはない、まばゆいばかりの輝きを持っています。ジュエリーだけでなく時計にも多く採用されています。 世界で最も硬い宝石であるダイヤモンドは、時計の文字盤の一部として使用されることが多く、複雑なセッティングによってその輝きを見せます。

02 ラピスラズリ

モース硬度: 5-5.5

ラピスラズリ は、主にナトリウム、アルミニウム、ケイ素、硫黄、塩化物、水酸化物を含む鉱物と、さまざまな量の黄鉄鉱および白色方解石から構成される珍しい変成岩です。ワックス状からガラス状の光沢を持つ、半透明から不透明の宝石です。

ラピスラズリの色は、わずかに緑がかった青から紫がかった青まで変化し、高品質のラピスラズリは、金色の斑点が最小限に抑えられた、均一で彩度の高い青が特徴です。

As early as 3100 BCE, there are records of lapis lazuli being mined, making it possibly the earliest used blue gemstone by humans. In ancient civilizations, including Mesopotamia, Egypt, China, Greece, and Rome, lapis lazuli was considered a precious gem. Before the early 19th century, it was ground into powder and used as a deep blue pigment. During the Renaissance, artists used it to create a high-quality blue pigment known as “Ultramarine.”

ラピスラズリにはアフガニスタンでの採掘の長い歴史があり、今日に至るまで主要な資源であり続けています。他の主な産地にはチリやロシアなどがあります。 ラピスラズリは、高級時計の文字盤に一貫して好まれている素材です。

03 タイガーアイ

モース硬度: 6.5-7

タイガーアイ シャトヤンシー、つまり猫の細長い目に似た明るい光の帯が宝石の曲面に現れる現象で知られる半貴石のクォーツです。虎の鋭い目に似ていることから名づけられました。

インターネットからの画像

タイガーアイは、クロシドライト繊維の変質の初期段階で形成され、最初は酸化鉄に変わり、その後シリカに置き換えられます。宝石は通常不透明で、色は濃い黄色から茶色までさまざまです。高品質のタイガーアイは、完璧な表面を示し、明確で明るいキャッツアイ効果が中央に配置されている必要があります。

タイガーアイの歴史は古代ローマやエジプトの時代にまで遡り、太陽神や勝利と関連付けられていました。タイガーアイの主な産地には、南アフリカ、ブラジル、中国が含まれます。

カボションカットを施したタイガーアイは、優れた光沢を放ち、さまざまな角度から見ると異なる反射でその魅力をさらに高めます。

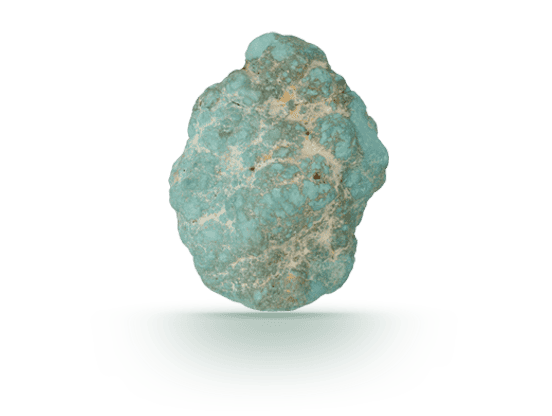

04 ターコイズ

モース硬度: 5-6

ターコイズ is a gemstone formed in crystalline structures near shallow water in arid and barren regions. It is a semi-translucent to opaque gem, commonly appearing in an opaque form with stripes, spots, or iron-like vein patterns. The finest quality turquoise exhibits a unique and intense blue hue, often described as “robin’s egg blue,” “sky blue,” or “Persian blue.”

ターコイズには長い歴史があり、採掘され複製された最初の宝石であるという特徴を持っています。紀元前 4000 年頃には、古代エジプトの墓の埋葬地からターコイズで作られたビーズが発見されていました。

現在、イランと米国が高品質のターコイズの重要な供給源であり、中国が世界最大の生産国です。さらに、メキシコ、オーストラリア、チリ、ロシア、トルコ、その他の地域もターコイズの生産に貢献しています。

05 クリソコラ(別名:ターコイズ)

モース硬度: 3.5-4.5

上記のターコイズはクリソコラと同じ石ではありませんが、名前は同じかもしれませんが、 クリソコラ はターコイズグリーンの色で知られる銅を含む鉱物で、高品質の標本には緑がかった帯のあるブロック状の構造が特徴であることがよくあります。見た目や色が似ているため、よくターコイズと混同されます。ターコイズのベースは青色ですが、ターコイズは緑色で、透明から半透明まであります。

クリソコラ/ターコイズは、人類の歴史の中で最も重要な鉱物の 1 つと考えられます。紀元前 4000 年には、人々はターコイズを加熱すると天然の銅が生成されることを発見したと考えられています。

これは、人間が鉱石から金属を製錬し、金属鉱石の探査を引き起こし、冶金学の発展を促進した最初の例である可能性があります。紀元前 3000 年頃の古代エジプトでは、ターコイズが認識され、お守り、宝石、アイシャドウとして使用されていました。

06 ジェダイト

モース硬度: 7

カルセドニー 低温のシリカを豊富に含む溶液が既存の岩石、特に火山岩の空洞や割れ目に浸透するときに形成されます。世界で最も初期の宝石素材の 1 つです。純粋なカルセドニーは白色ですが、さまざまな微量元素や鉱物インクルージョンが含まれると、豊かな色を帯びます。

カルセドニーには、瑪瑙、クリソプレーズ、ブラッドストーン、グリーンカルセドニー、レッドカルセドニー、ブルーカルセドニー、カーネリアンなどの固有名があり、特にグリーンカルセドニーは貴重です。

さらに区別すると、瑪瑙はカルセドニーの最も代表的な品種であり、明確な縞状構造を持つものを瑪瑙と呼びます。縞模様の構造がない場合は、カルセドニーと見なされます。アゲートは、ほとんどの標本で同心円状の色の縞模様が特徴で、さまざまな不純物により多様な色を示しますが、カルセドニーには縞模様のテクスチャがなく、均一な色を示します。

カルセドニーの工芸品は石器時代にまで遡り、装飾品は 2 万年から 16 万年前まで発見されています。紀元前 3000 年までに、古代エジプト人はすでに瑪瑙、赤玉髄、緑玉髄を装飾品として使用していました。

カルセドニーは世界中で発見されており、ブラジル、ウルグアイ、インドでは大量の鉱床があり、さまざまな種類のカルセドニーが産出されています。ブラッドストーンの主要生産国である中国など、他の地域でもさまざまな種類のカルセドニーが産出されています。カルセドニーとクリソプレーズは時計の文字盤によく使用されます。

07 ユークレース

モース硬度: 5.5-6.5

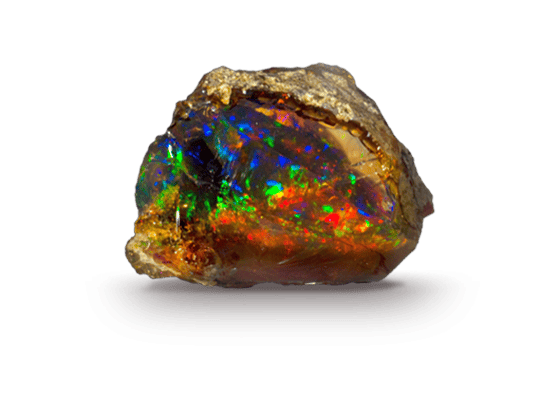

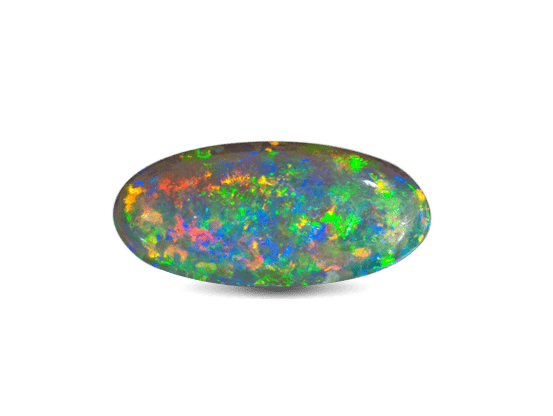

Euclase forms as silica seeps into rocks beneath the ground through rainwater. As the water evaporates, silica deposits in the form of small spheres and binds with more silicon and water, creating “euclase.”

What makes euclase particularly enchanting is its iridescence. When the gem is moved, various colors of shimmering reflections can be observed. This iridescence is only formed when the silica spheres are of the appropriate size and arranged in a regular pattern. The more orderly the arrangement, the larger the iridescent area, and the more pronounced the color changes. This iridescence is considered the soul and value of euclase. “Precious euclase” is defined by having the iridescence, with red iridescence being the most valuable.

記録によると、最古のユークレース鉱山地域はハンガリーにあり、採掘の歴史は14世紀にまで遡り、現在もユークレースの産地であり続けています。ユークレースの最大生産国はオーストラリアで、メキシコや南アフリカも主要生産地です。

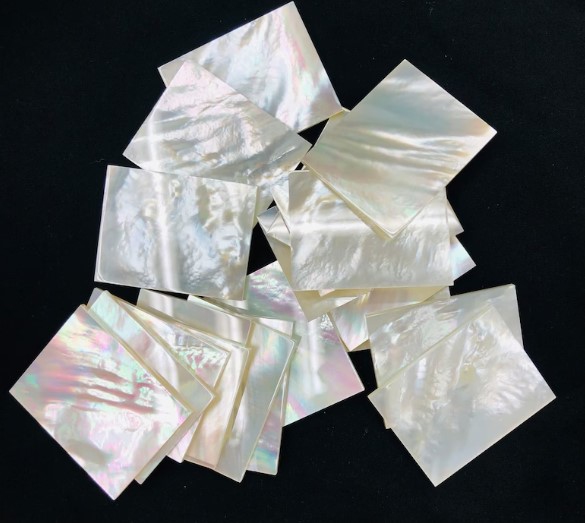

08 マザーオブパール(別名:真珠層)

モース硬度: 2.5-4

真珠の母 自然に真珠を生成できる特定の軟体動物の殻の内層を指します。これらの軟体動物は通常、浅海に生息し、太平洋、大西洋、インド洋のサンゴ礁や海底で見られます。真珠が形成される長い期間にわたって、真珠層の内側が真珠層で覆われ、真珠層に色が与えられ、美しく人気の高い素材となります。

真珠に比べて、マザーオブパールは耐久性と弾力性に優れています。 13世紀以来、ヨーロッパ貴族の間で装飾美術の素材として珍重されてきました。マザーオブパールは家具の装飾、宝石箱の製作、さらにはナイフのハンドルの製作にも使用され、当時の生活に欠かせないものとなりました。マザーオブパールは時計の文字盤によく使われる素材です。

マザー オブ パールには工業グレードと宝石グレードの 2 つの種類があり、後者の方が希少です。時計の文字盤に使用されている素材は宝石グレードの品質です。それぞれの天然石は、選別、分割、切断、研削、研磨、仕上げ、穴あけ、彫刻、セッティングなどの細心の注意を払って、魅力的な時計の文字盤として最終的な形に仕上げられます。

09 隕石

モース硬度:4.5~5.5程度

あ 隕石 彗星、小惑星、隕石などの天体の破片で、地球の大気圏を通過して生き残り、地球の表面に着陸します。これらの破片のサイズは、小さな粒子から数トンの重さの大きな塊までさまざまです。隕石は、初期の太陽系とそれ以降に関する貴重な科学情報を提供します。

隕石には、その組成に基づいて主に 3 つのタイプがあります。

- 石質隕石 (コンドライト): これらは最も一般的なタイプで、主にケイ酸塩鉱物で構成されています。コンドライトには、コンドリュールと呼ばれる小さな球状の構造が含まれていることが多く、これは太陽系で形成された最も初期の固体物質の 1 つであると考えられています。

- 鉄隕石: これらの隕石は主に金属の鉄とニッケルの合金で構成されており、密度が高く、多くの場合、ウィドマンシュテッテン パターンと呼ばれる独特の磨かれた表面を持っています。このパターンは、宇宙で何百万年にもわたって金属がゆっくりと冷却された結果です。

隕石ダイヤル - インターネットからの画像 - 石鉄隕石: これらの隕石には、ケイ酸塩鉱物と金属鉄ニッケル合金の混合物が含まれています。それらは比較的稀で、金属マトリックスに埋め込まれたカンラン石結晶を持つパラサイトと、金属とケイ酸塩鉱物の複雑な混合物を持つメソシデライトの 2 つの主なグループに分けられます。

隕石は、落下の特徴、組成、構造に基づいてさらに分類できます。これらは、初期の太陽系の状態と、惑星やその他の天体の形成につながったプロセスについての洞察を提供します。科学者は、太陽系の起源と進化について詳しく知るために隕石を研究しています。

最終的な考え:

ジュエリーに詳しい方であれば、これらの宝石はすべて、イヤリングやネックレス、ブレスレット、指輪などのジュエリーにも使用されていることがわかります。さまざまな宝石が、独自の色、特性、美しさによって選択され、ジュエリー デザイナーが創作できるようになります。多様で素晴らしい作品。

自然からの贈り物である天然石はそれぞれに個性があり、自然の美しさをさまざまな形で表現しています。天然宝石で作られた文字盤を備えた時計を購入したことがありますか?

ソース:

ラピスラズリ: https://en.wikipedia.org/wiki/Lapis_lazuli

タイガーアイ: https://en.wikipedia.org/wiki/Tiger%27s_eye

ターコイズ: https://en.wikipedia.org/wiki/Turquoise

クリソコラ: https://en.wikipedia.org/wiki/Chrysocolla

カルセドニー: https://en.wikipedia.org/wiki/Chalcedony

隕石: https://en.wikipedia.org/wiki/Meteorite