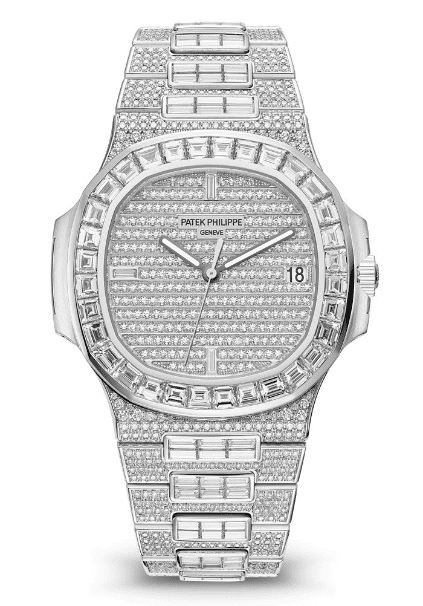

Betyr flere diamanter bedre i urbevegelser?

Role of Diamonds in Watch Movements

The role of diamonds in watch movements is multifaceted and crucial to the overall performance and quality of the timepiece. Diamonds are prized for their exceptional hardness, durability, and resistance to wear, making them ideal materials for various components within a watch movement.

Advantages of More Diamonds in Watch Movements:

The advantages of incorporating more diamonds into watch movements are manifold and extend beyond mere aesthetic appeal. Here are some key benefits:

- Forbedret holdbarhet: Diamonds are renowned for their exceptional hardness and durability. When used in watch movements, they offer increased resistance to wear and friction. This translates to a longer lifespan for the watch, as the diamonds help maintain the integrity of critical components over time.

- Improved Precision: The precise and uniform nature of diamonds allows for smoother movement within the watch mechanism. This results in enhanced accuracy and precision in timekeeping, which is essential for high-quality timepieces.

- Ripemotstand: Diamonds are highly resistant to scratches, making them an ideal material for protecting delicate watch components. Watches with diamond-enhanced movements are less prone to surface damage, ensuring they retain their pristine appearance for longer periods.

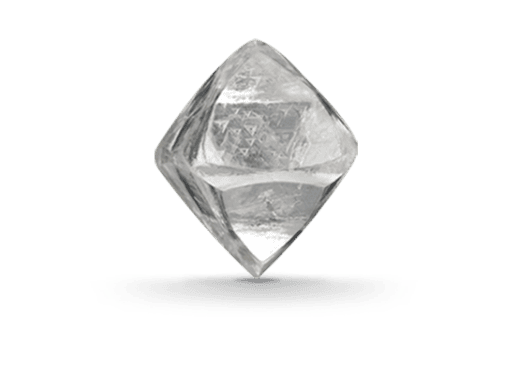

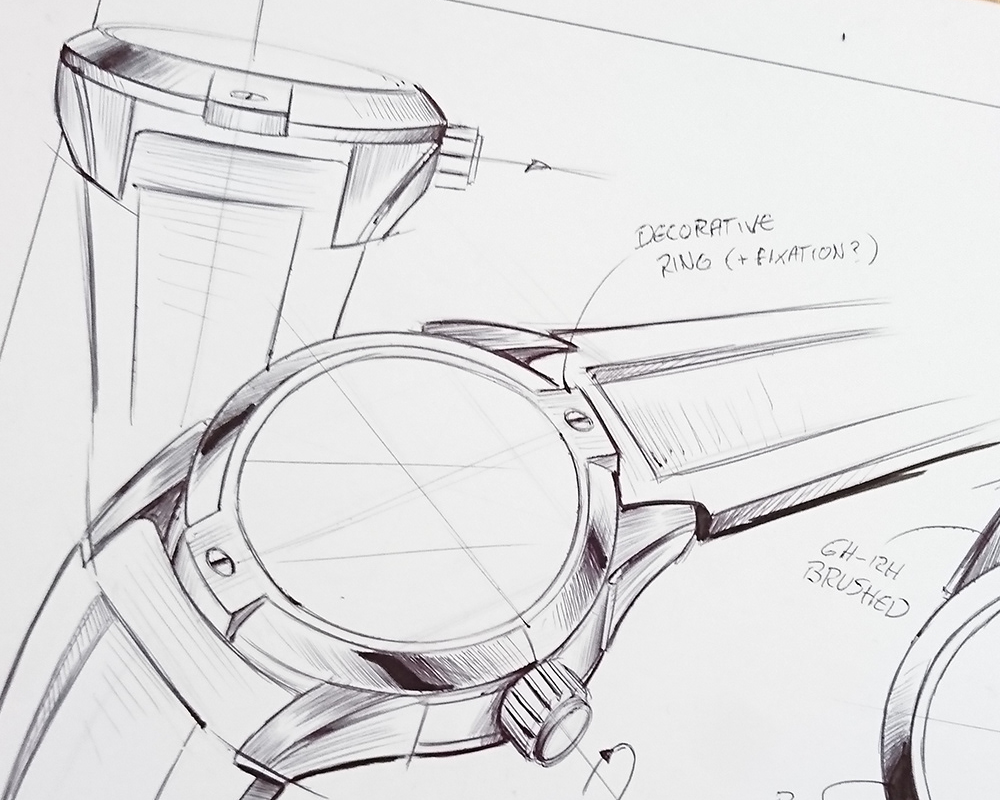

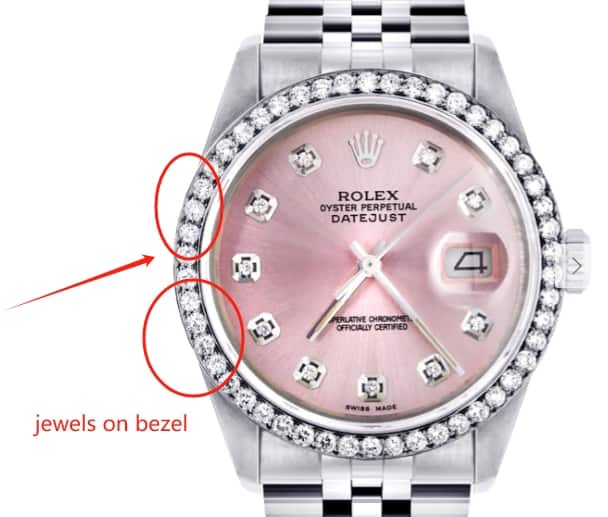

- Aesthetic Appeal: Beyond their functional benefits, diamonds add a touch of luxury and elegance to watch movements. Watches adorned with diamonds on visible parts such as the dial, bezel, or indices exude sophistication and prestige, appealing to discerning consumers.

- Value Retention: Watches with diamond-enhanced movements often retain their value well over time. The durability and timeless beauty of diamonds contribute to the longevity of the timepiece, making it a valuable investment for collectors and enthusiasts.

- Distinctive Design: The use of diamonds allows for intricate and captivating designs in watch movements. Whether it’s a pave setting on the dial or a bezel adorned with sparkling stones, the presence of diamonds adds a unique and distinctive flair to the watch’s overall design.

Disadvantages of Excessive Diamonds in Watch Movements:

- Increased Weight: Excessive diamonds in watch movements can significantly increase the overall weight of the timepiece. This can affect wearer’s comfort, especially if the watch is worn for extended periods.

- Bulkiness: Watches with excessive diamonds may become bulkier due to the additional material used in their construction. This can detract from the sleek and slim profile that many watch enthusiasts prefer.

- Higher Costs: Watches adorned with excessive diamonds typically come with higher price tags. The cost of sourcing and setting numerous diamonds can significantly inflate the price of the watch, making it less accessible to some consumers.

- Diminished Readability: In some cases, an abundance of diamonds on the watch dial or hands can hinder readability, especially in certain lighting conditions. The glare and reflections from the diamonds may obscure the time, making it difficult to read at a glance.

- Maintenance Challenges: Diamond-encrusted watches require special care and maintenance to preserve their beauty. Cleaning and servicing such watches can be more complex and costly due to the delicate nature of the diamonds and their settings.

- Subjective Taste: While some individuals may appreciate the lavishness of a diamond-studded watch, others may find it ostentatious or gaudy. Excessive diamonds can polarize opinions and may not appeal to everyone’s aesthetic preferences.

- Risk of Damage: Watches with excessive diamonds are more susceptible to damage, particularly if the diamonds are not securely set. Loose or damaged diamonds can detract from the watch’s appearance and may require costly repairs.

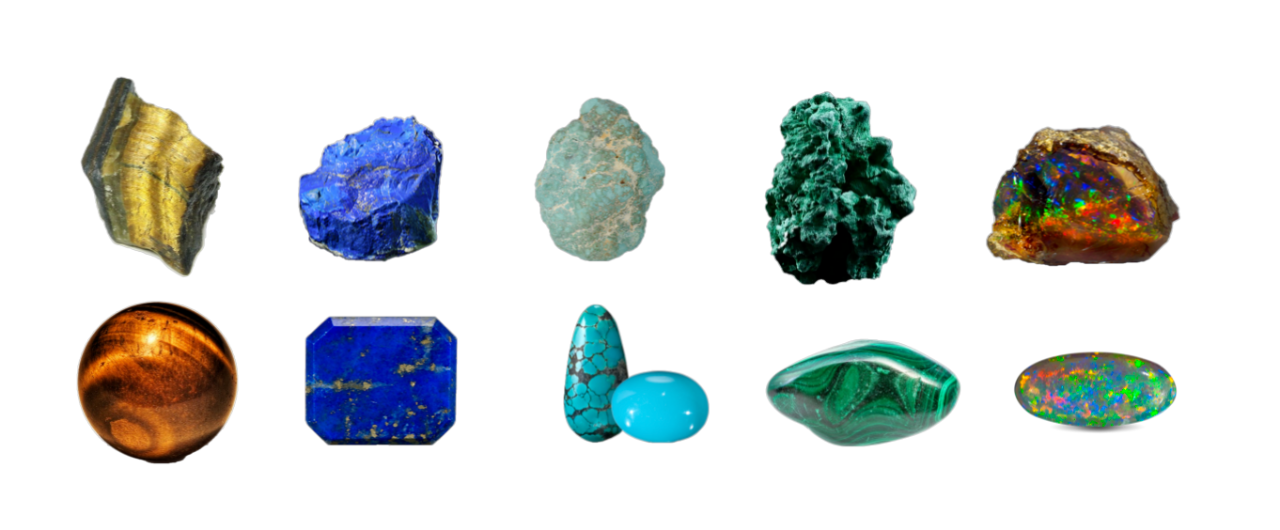

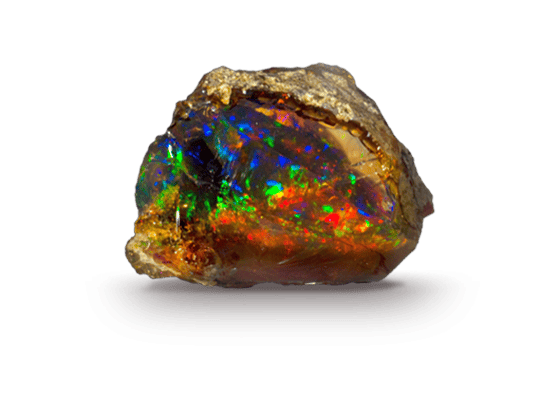

Watchmakers use Several types of Diamonds:

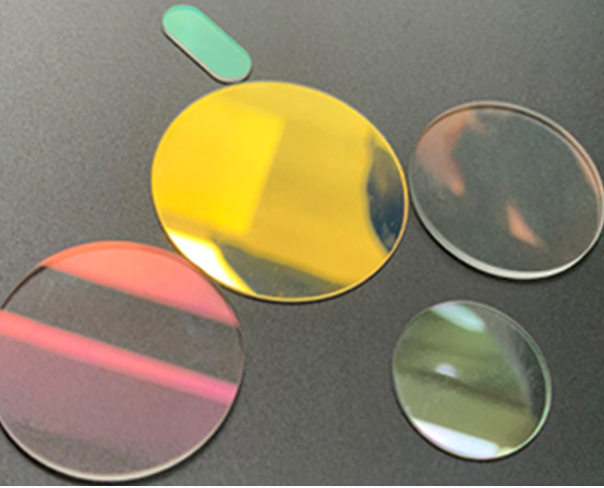

- Ruby: Rubies are commonly used as bearings in watch movements, such as in balance wheel bearings and escapement wheel bearings. Ruby bearings can reduce friction between mechanical parts, improving the accuracy and stability of the watch.

- Synthetic Ruby: Synthetic rubies can also be used as bearings in watch movements, similar to natural rubies but more cost-effective.

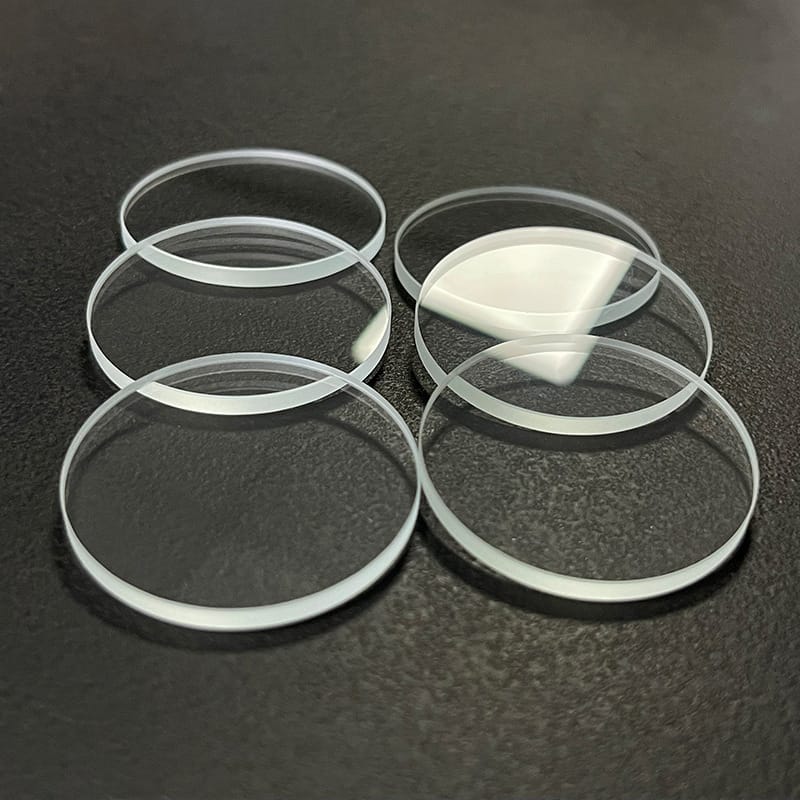

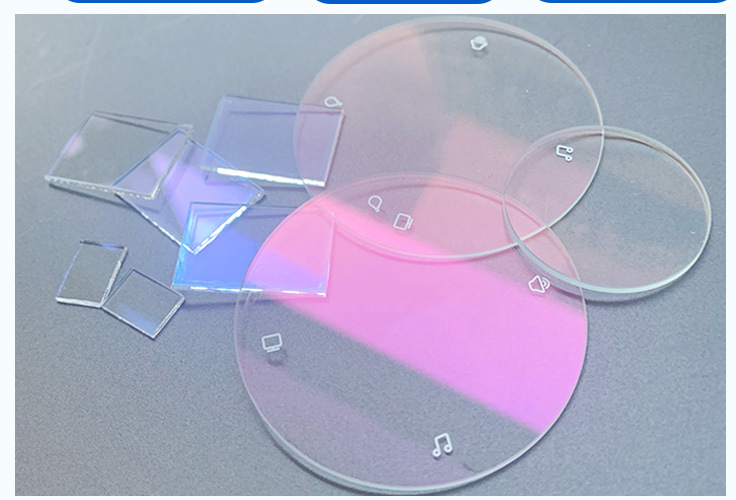

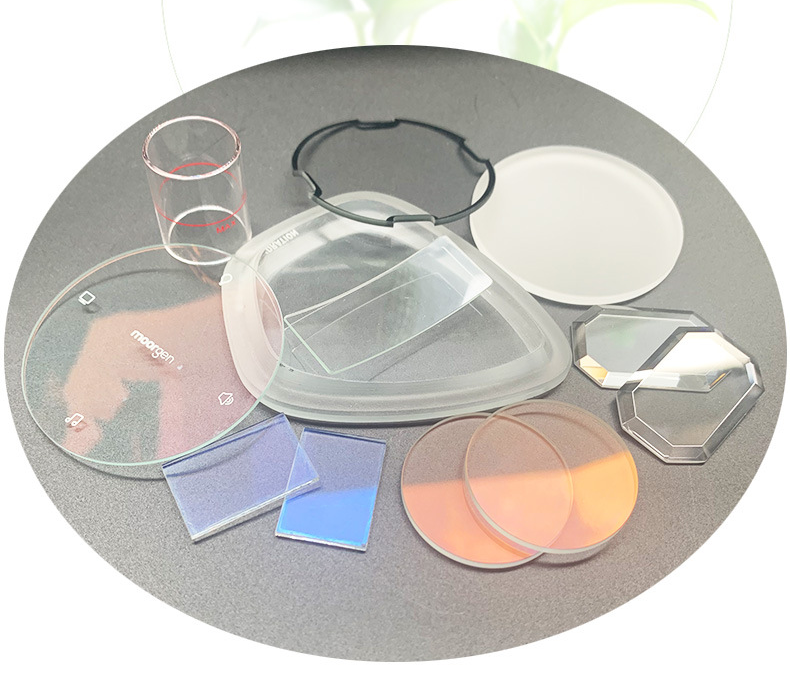

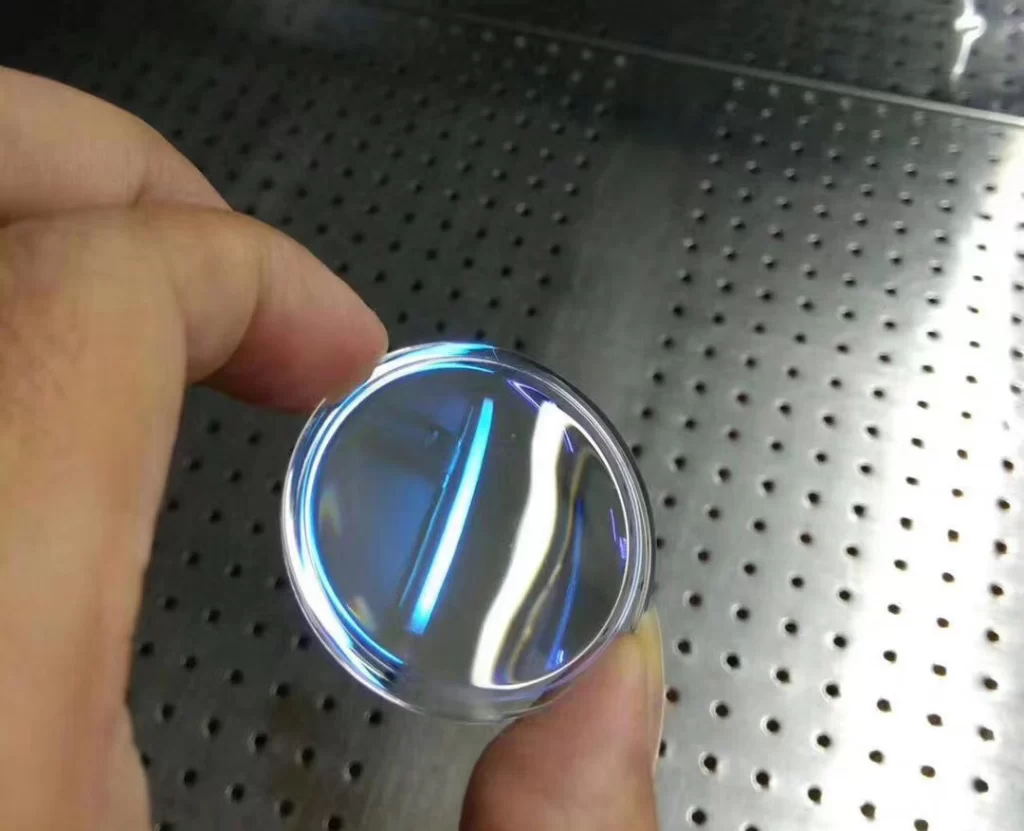

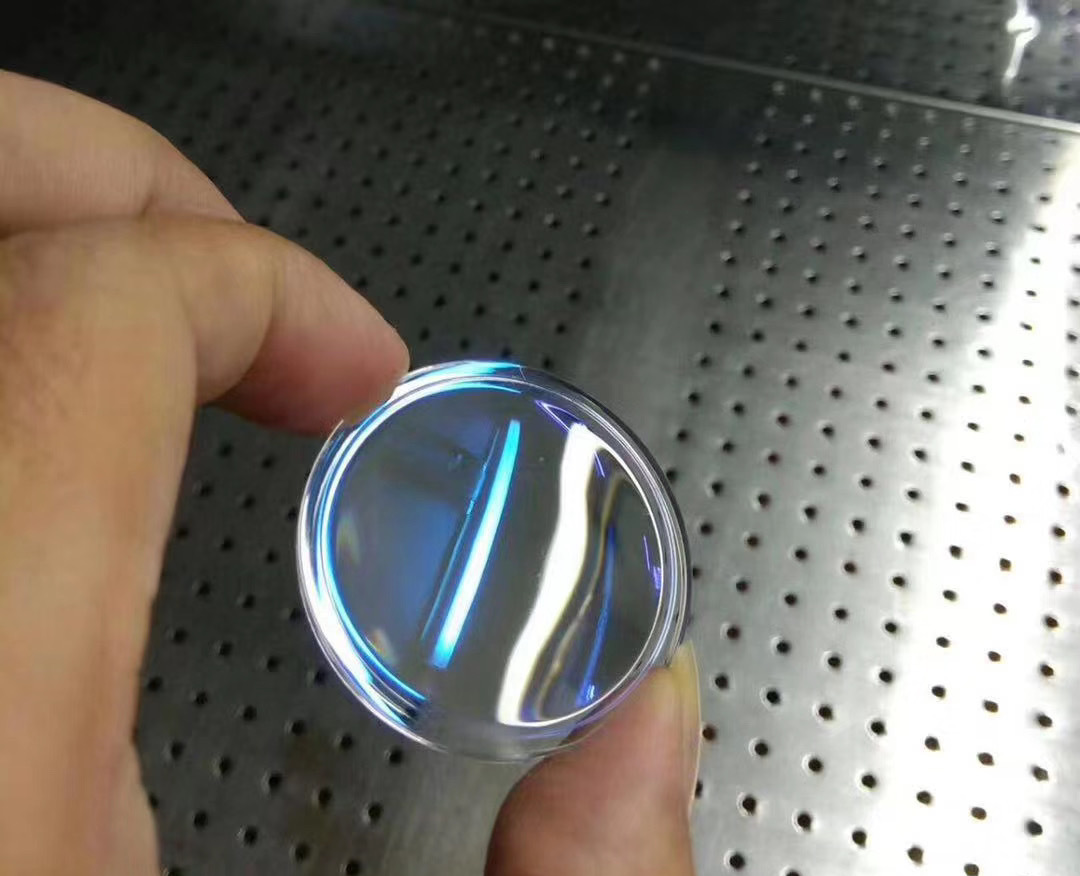

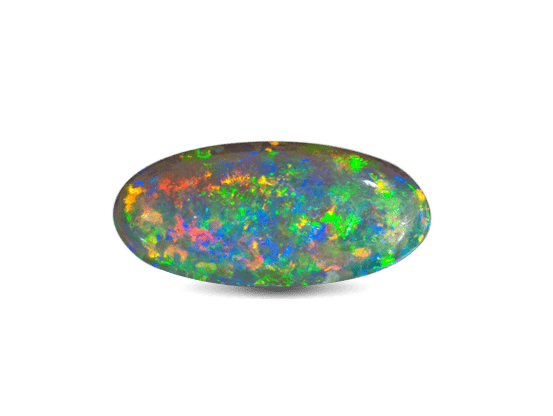

- Sapphire: Sapphires are typically used in watch transparent cover plates and transparent case backs as protective and decorative materials. The transparency and durability of sapphire make it an ideal choice for showcasing the exquisite craftsmanship and complex construction of the movement.

sapphire - Synthetic Sapphire: Synthetic sapphires, similar to natural sapphires, are commonly used in watch transparent cover plates and transparent case backs to protect and decorate the movement.

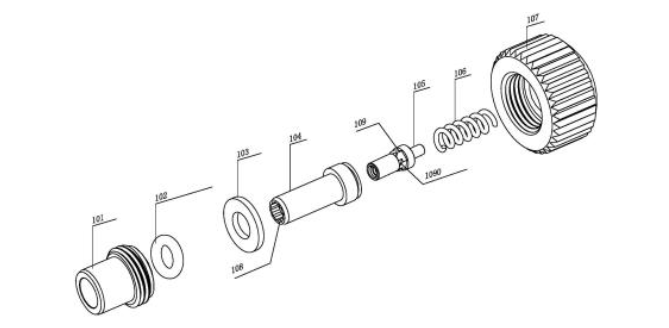

The shape of the Diamonds in the watch movement::

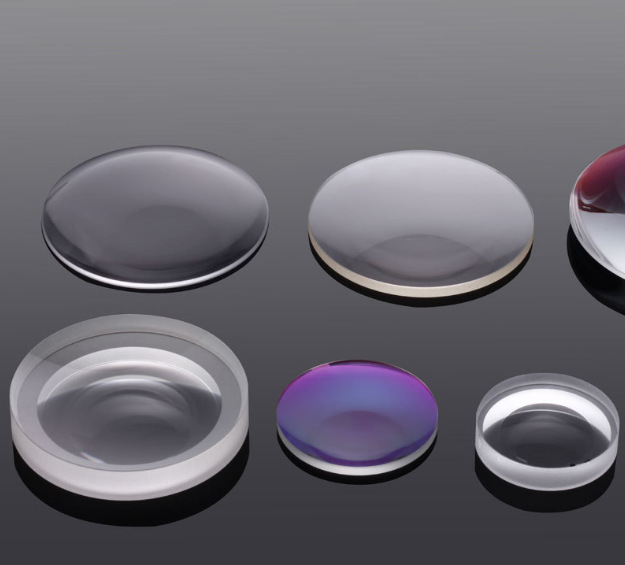

The jewels in a watch movement typically come in various shapes, including:

- Round: The most common shape for jewels used in watch movements is round. Round jewels are versatile and can be used in various parts of the movement.

- Oval: Some watch movements may use oval-shaped jewels, especially in areas where space is limited or where a specific shape is required for optimal performance.

- Square or Rectangular: Square or rectangular-shaped jewels may be used in specific areas of the movement, providing stability and support in angular or confined spaces.

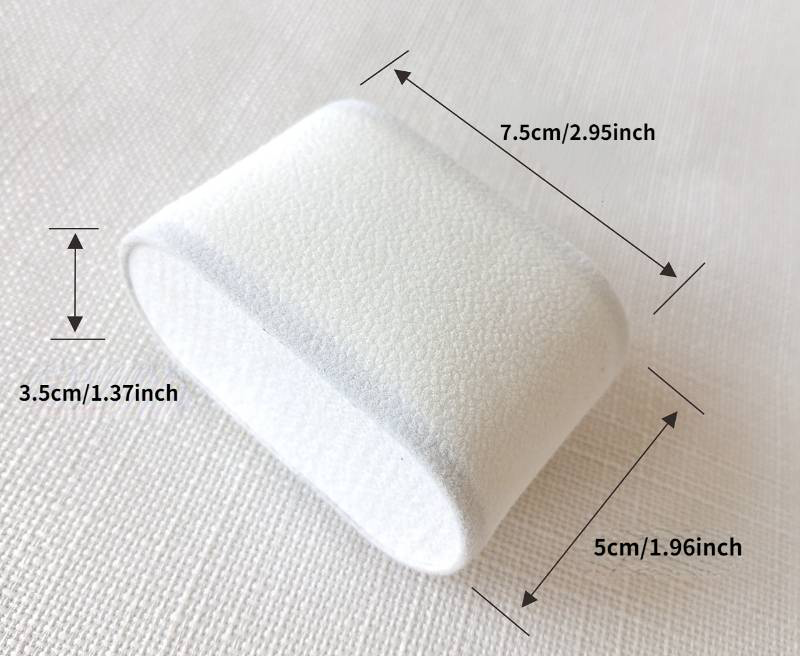

- Barrel-shaped: Barrel-shaped jewels are less common but may be used in specialized parts of the movement where a unique shape is necessary for precise functioning.

- Pear-shaped: Pear-shaped jewels are also occasionally used in watch movements, particularly in areas where a tapered or pointed shape is advantageous.

Reference:https://en.wikipedia.org/wiki/Jewel_bearing

Overall, the shape of the jewels in a watch movement is determined by the specific requirements of each part of the movement and the design preferences of the watchmaker.

Where do the Diamonds in watch movements come from?

The rubies typically used in watch movements are sourced from mineral deposits of natural ruby. Ruby deposits can be found worldwide, with major producing countries including Myanmar, Thailand, Sri Lanka, and Tanzania. These regions are renowned for their high-quality ruby deposits. During the mining process, ruby-bearing rocks are extracted and undergo processing and cutting to produce the ruby bearings and other components used in watch movements.

What the function of the Diamonds in watch movements

The jewels in watch movements play a crucial role in several aspects:

- Friction Reduction: The jewels, typically made of synthetic sapphire or ruby, serve as bearings or seats in the movement. Their high hardness and smooth surface help reduce friction between mechanical parts, ensuring smooth operation of the movement.

- Enhanced Accuracy: Due to their uniform structure and hardness, jewels provide stable support and balance, contributing to improved accuracy and stability of the watch.

- Extended Lifespan: The hardness and wear resistance of jewels protect critical components of the movement, such as the balance wheel bearings and escapement wheel bearings, reducing wear and tear and extending the watch’s lifespan.

- Increased Reliability: The stability and durability of jewels in the movement ensure long-term stable operation, enhancing the reliability and durability of the watch.

Overall, the jewels in watch movements play a vital role in ensuring the precise operation and long-term reliability of the watch.

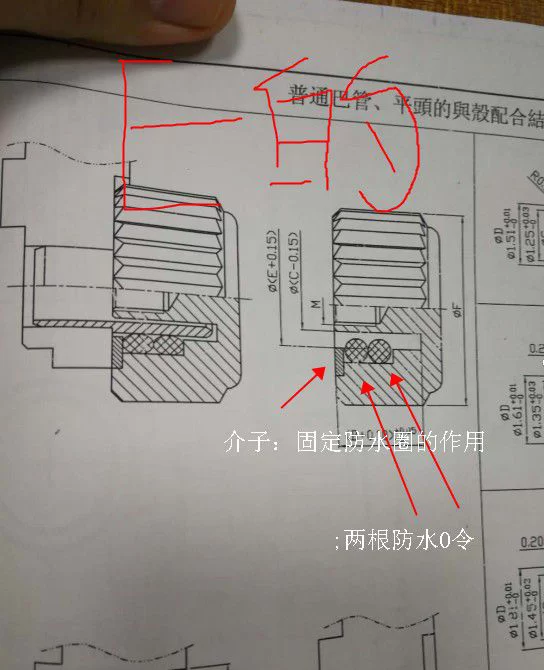

How to determine whether a high-end watch uses decorative or functional gemstones?

To determine whether the gemstones used in a high-end watch are decorative or functional, several factors can be considered:

- Position and Quantity: Firstly, attention should be paid to the position and quantity of the gemstones. If the gemstones are primarily concentrated on the dial, bezel, hands, and other aesthetic parts of the watch, and there are a large number of them, they are likely decorative gemstones used to enhance the visual appeal and luxury of the watch. Conversely, if the gemstones are mainly used in key parts of the movement, such as bearings and pallets, where their presence is crucial for improving the accuracy and stability of the watch, they are likely functional gemstones.

- Material and Quality: Secondly, the material and quality of the gemstones should be considered. Decorative gemstones are often chosen for their vibrant colors and attractive appearance, such as diamonds and colored gemstones, to enhance the visual effect and luxury of the watch. Functional gemstones, on the other hand, prioritize hardness, transparency, and purity to ensure they can provide high-quality functional support.

- Brand and Positioning: Lastly, the brand and positioning of the watch should also be taken into account. Some high-end watch brands focus more on aesthetics and luxury in their designs, and gemstones may be used primarily for decoration. In contrast, technical watch brands prioritize functionality and performance, and gemstones may be used more for improving the quality and precision of the movement.

In conclusion, by observing the position and quantity, material and quality of the gemstones, as well as the brand and positioning of the watch, one can make a relatively accurate judgment on whether the gemstones used in a high-end watch are decorative or functional.

Are the Diamonds in high-end watch movements valuable?

Since the appearance of synthetic gemstones in 1892, watch manufacturers have predominantly used aluminum oxide and coloring agents (such as chromium oxide) sintered at high temperatures to form red rubies. However, prior to the 1800s, expensive natural rubies were used in watch movements. Therefore, mechanical watches with ruby bearings were considered high-end timepieces at the time and commanded high prices.

Since most gemstones used in high-end watch movements today are synthetic, does that mean these gemstones are meaningless?

The gemstones used in high-end watch movements typically hold some value, but their worth depends on several factors:

Gemstone Quality: The quality of the gemstone significantly impacts its value. High-quality natural gemstones, such as premium rubies and sapphires, as well as synthetic gemstones like synthetic rubies and sapphires, generally hold higher value. Their clarity, color, and purity directly influence their market worth.

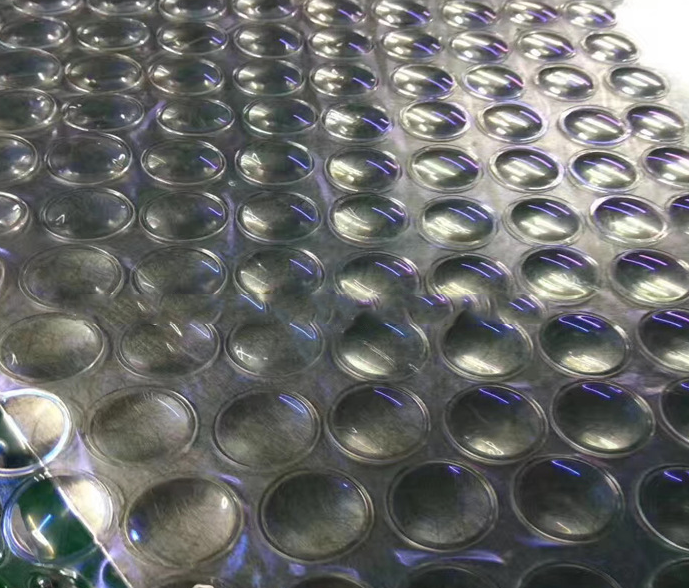

Quantity and Size of Gemstones: The number and size of gemstones used in watch movements also affect their value. Generally, movements with more gemstones and larger sizes tend to have relatively higher value because it implies that the watch manufacturer has invested more cost and craftsmanship into the production process.

Watch Brand and Model: The brand and model of the watch are also important factors in determining the value of gemstones in the movement. Some well-known watch brands and specific models may have higher collector’s value due to their rarity and uniqueness, potentially increasing the overall value of the movement.

Market Demand and Trends: Lastly, market demand and trends also impact the value of gemstones in watch movements. If a certain type of watch or specific brand is favored by collectors or consumers, the gemstones used in them may appreciate in value as a result.

In fact, these gemstones play an irreplaceable role due to their high hardness (Mohs hardness of 9), wear resistance, good surface roughness, and low friction coefficient (friction coefficient generally reaching 0.14 under dry friction when used in conjunction with metal parts, and friction coefficient can be reduced to 0.01 under good lubrication conditions).

When used as bearings in the movement, the transmission efficiency of gears is greatly improved, making the watch more accurate and significantly extending its service life. It can be said that the number of jewels is an important indicator of the quality of a mechanical watch, and the quantity of gemstones is usually marked on the dial.

Therefore, in the past, some watch manufacturers, in order to attract consumers’ attention, marked the quantity of non-functional diamonds (decorative diamonds) on the movement, dial, and case of mechanical watches. This practice, such as having small dials with many diamonds (there are watches with 88 diamonds on the market), is obviously misleading to consumers who are not knowledgeable about watches.

To curb this situation, the international standard ISO-1112 stipulates that only the quantity of functional gemstones can be marked on the dial; regardless of the number of non-functional gemstones, marking is not allowed.

From the above, we can see that the more gemstones used in a movement does not necessarily mean better. The average number of jewels in a typical mechanical watch movement is around 19 (around 25 for automatic mechanical movements). Additionally, if there are other complex mechanisms, the number of jewels in custom-made watches may increase. However, it is certain that the importance of decorative gemstones is slightly lower than that of functional gemstones.

In summary, the gemstones used in high-end watch movements usually have some value, but their specific value depends on the comprehensive impact of various factors.

Expert Tips for Selecting Diamond Watches

- Set a Budget: Determine your budget before starting your search for a diamond watch. Prices can vary significantly based on factors such as the quality and quantity of diamonds, as well as the brand and craftsmanship of the watch.

- Consider Diamond Quality: Pay attention to the quality of the diamonds used in the watch. Look for diamonds with high clarity, color, and cut grades to ensure maximum brilliance and sparkle.

- Evaluate Craftsmanship: Assess the craftsmanship of the watch, including the setting of the diamonds and the overall construction. Ensure that the diamonds are securely set to minimize the risk of damage or loss.

Mekanisk bevegelse - Choose a Reputable Brand: Opt for a reputable brand known for its quality and craftsmanship. Established watchmakers with a history of producing high-quality timepieces are more likely to offer reliable diamond watches.

- Research the Movement: Look into the movement of the watch and consider factors such as accuracy, reliability, and functionality. A high-quality movement is essential for ensuring the long-term performance of the watch.

Mekanisk bevegelse - Consider Your Lifestyle: Take your lifestyle into account when selecting a diamond watch. If you lead an active lifestyle or work in environments where the watch may be subjected to rough conditions, choose a watch with a durable design and sturdy construction.

- Seek Expert Advice: Consult with knowledgeable experts or watch enthusiasts for advice and recommendations. They can provide valuable insights into the quality, value, and performance of different diamond watches.

- Try Before You Buy: Whenever possible, try on the watch before making a purchase. Pay attention to how it feels on your wrist and how the diamonds catch the light. Ensure that the watch is comfortable to wear and suits your personal style.

- Research Warranty and Service Options: Look into the warranty and service options offered by the manufacturer or retailer. A comprehensive warranty and reliable service options can provide peace of mind and ensure that your investment is protected.

- Trust Your Instincts: Ultimately, trust your instincts and choose a diamond watch that speaks to you. Select a watch that resonates with your personal style, preferences, and values, ensuring that you’ll enjoy wearing it for years to come.

Maintenance and Care of Diamond Watches:

- Regular Cleaning: Clean your diamond watch regularly to remove dirt, oils, and debris that can accumulate on the surface. Use a soft, lint-free cloth dampened with mild soapy water to gently wipe the watch, taking care not to submerge it in water.

- Avoid Harsh Chemicals: Avoid exposing your diamond watch to harsh chemicals such as bleach, ammonia, or chlorine, as these can damage the metal and degrade the quality of the diamonds. Remove your watch before engaging in activities such as swimming or cleaning with chemical-based products.

- Protect from Impact: Diamonds are durable, but they can still chip or crack if subjected to hard impacts. Avoid wearing your diamond watch during activities where it may be prone to impact or contact with hard surfaces.

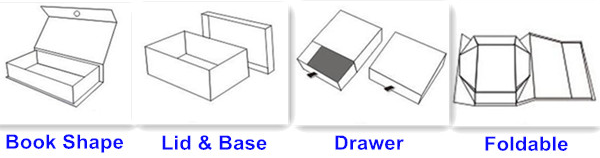

Mekanisk bevegelse - Store Properly: When not in use, store your diamond watch in a clean, dry place away from direct sunlight and extreme temperatures. Consider using a soft cloth or watch box to protect it from dust and scratches.

- Professional Servicing: Periodically have your diamond watch serviced by a professional watchmaker to ensure it remains in optimal condition. Regular servicing can help identify and address any issues before they escalate, prolonging the lifespan of your timepiece.

- Check for Loose Stones: Regularly inspect your diamond watch for any loose or missing stones. If you notice any, take your watch to a reputable jeweler or watchmaker for repair to prevent further damage.

- Avoid Magnetic Fields: Keep your diamond watch away from strong magnetic fields, as these can interfere with the movement and accuracy of the watch. Avoid placing your watch near electronic devices or magnetic jewelry.

- Avoid Extreme Temperatures: Avoid exposing your diamond watch to extreme temperatures, as this can affect its performance and durability. Avoid wearing your watch in hot tubs or saunas, as prolonged exposure to heat can damage the internal components.

- Be Gentle: Handle your diamond watch with care, avoiding unnecessary rough handling or excessive force. When setting the time or adjusting the crown, use gentle, steady pressure to avoid damaging the delicate mechanisms.

- Professional Cleaning: Consider having your diamond watch professionally cleaned and inspected periodically to ensure it remains in optimal condition. Professional cleaning can remove stubborn dirt and grime and restore the brilliance of the diamonds.

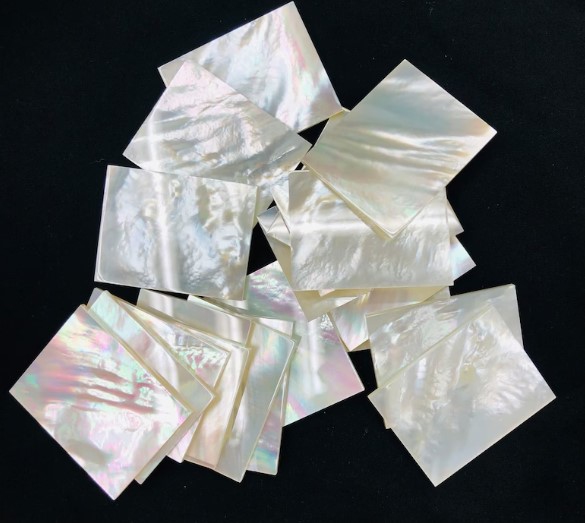

Comparison of Diamond Watches with Alternative Materials

Diamond Watches:

- Luxurious Appearance: Diamond watches exude luxury and sophistication, thanks to the brilliance and sparkle of the diamonds. They add a touch of elegance to any outfit and are often seen as status symbols.

- Exceptional Hardness: Diamonds are one of the hardest materials on earth, making them highly resistant to scratches and abrasions. This ensures that diamond watches maintain their pristine appearance even after years of wear.

- Long-lasting Investment: Diamond watches are considered valuable investments due to the enduring beauty and durability of diamonds. They tend to retain their value well over time and can even appreciate in value, especially if they are rare or from prestigious brands.

Alternative Materials:

- Stainless Steel: Stainless steel is a popular material used in watchmaking due to its durability and affordability. While not as luxurious as diamonds, stainless steel watches are highly resistant to corrosion and offer a sleek, modern aesthetic.

Stainless steel - Ceramic: Ceramic watches are known for their scratch-resistant properties and lightweight feel. They offer a contemporary look and are available in a wide range of colors. However, ceramic watches may be more prone to shattering or chipping compared to diamonds.

Ceramic - Titanium: Titanium watches are prized for their strength, lightweight feel, and hypoallergenic properties. They are highly resistant to corrosion and are often used in sports and outdoor watches. However, titanium lacks the sparkle and glamour associated with diamonds.

Titanium - Gold: Gold watches are classic timepieces that exude elegance and luxury. While not as durable as diamonds, gold watches are highly prized for their timeless appeal and investment value. However, they may require more frequent maintenance to prevent scratching and tarnishing.

Gold

Comparison:

- Varighet: Diamonds are the hardest material, offering superior durability and scratch resistance compared to alternative materials like stainless steel, ceramic, titanium, and gold.

- Luxury: Diamond watches are synonymous with luxury and prestige, offering a level of sophistication that other materials may not match.

- Value: While diamond watches are valuable investments, alternative materials like stainless steel and titanium offer more affordable options without sacrificing durability.

- Aesthetics: Diamond watches stand out for their sparkling brilliance and timeless elegance, while alternative materials offer a variety of styles and designs to suit different preferences.

In summary, while diamond watches offer unmatched luxury and durability, alternative materials provide more affordable options with unique aesthetics and practical benefits. The choice between diamond watches and alternative materials ultimately depends on individual preferences, budget, and lifestyle considerations.

FAQs:Ofte stilte spørsmål

Can excessive diamonds affect the functionality of a watch?

Answer: Excessive diamonds may affect the functionality of the watch. While diamonds themselves are highly durable materials, excessive diamond decoration may increase the weight of the watch, leading to unstable or inaccurate movement operation. Additionally, an abundance of diamonds may also impact the watch’s water resistance and durability.

The quantity of jewels in a watch movement isn’t necessarily better. Jewels are used to reduce friction between mechanical parts, enhancing the accuracy and stability of the movement. Therefore, a watch requires enough jewels to support key components, but too many jewels can increase the watch’s cost without necessarily providing additional performance benefits.

For a typical watch, 17 to 25 jewels are usually sufficient. However, complex watches may require more jewels to support additional functionality, depending on the watch’s design and manufacturing requirements. Therefore, the quantity of jewels should be balanced according to the watch’s complexity and manufacturing needs.

What maintenance routines are recommended for diamond watches?

Answer: For diamond watches, the following maintenance procedures are recommended:

- Regular Cleaning: Periodically clean the watch surface with mild soapy water and a soft cloth to remove dust and dirt.

- Avoid Contact with Chemicals: Avoid exposing the watch to chemicals such as perfume, cosmetics, and cleaning agents to prevent damage to the diamonds and watch surface.

Dish-washing-Liquid. - Regular Inspection: Regularly check if the diamonds on the watch are loose or damaged, and repair or replace them promptly.

- Avoid Impact: Avoid the watch coming into contact with hard objects to prevent diamonds from becoming loose or damaged.

- Storage Attention: Store the watch in a dry place away from direct sunlight, and avoid prolonged exposure to water or moisture.

Are there alternative materials to diamonds for enhancing watch movements?

Answer: Apart from diamonds, there are several alternative materials that can be used to enhance watch movements, such as:

Synthetic Rubies and Sapphires: Synthetic gemstones similar to natural ones can be used in watch movements to improve stability and accuracy.

Ceramics: Ceramic materials offer excellent wear resistance and corrosion resistance, making them suitable for watch cases and straps, providing a longer lifespan and maintaining the appearance of the watch.

Stainless Steel and Titanium Alloys: Stainless steel and titanium alloys are commonly used watch materials, known for their corrosion resistance, wear resistance, and lightweight properties, making them suitable for manufacturing high-quality watch movements.

How many jewels should a watch have?

In general, a mechanical watch movement may contain several jewels, typically ranging from around 17 to 25 jewels. However, this depends on the complexity and functionality of the watch movement. Less complicated watches typically use fewer jewels, while more complex watches, such as those with tourbillons or chronograph functions, may use more jewels to improve the accuracy and stability of the movement. Therefore, the number of jewels on a watch is determined by the design and manufacturing requirements of the watch.

Most jewelry watches have approximately 17 jewels, used in multiple areas:

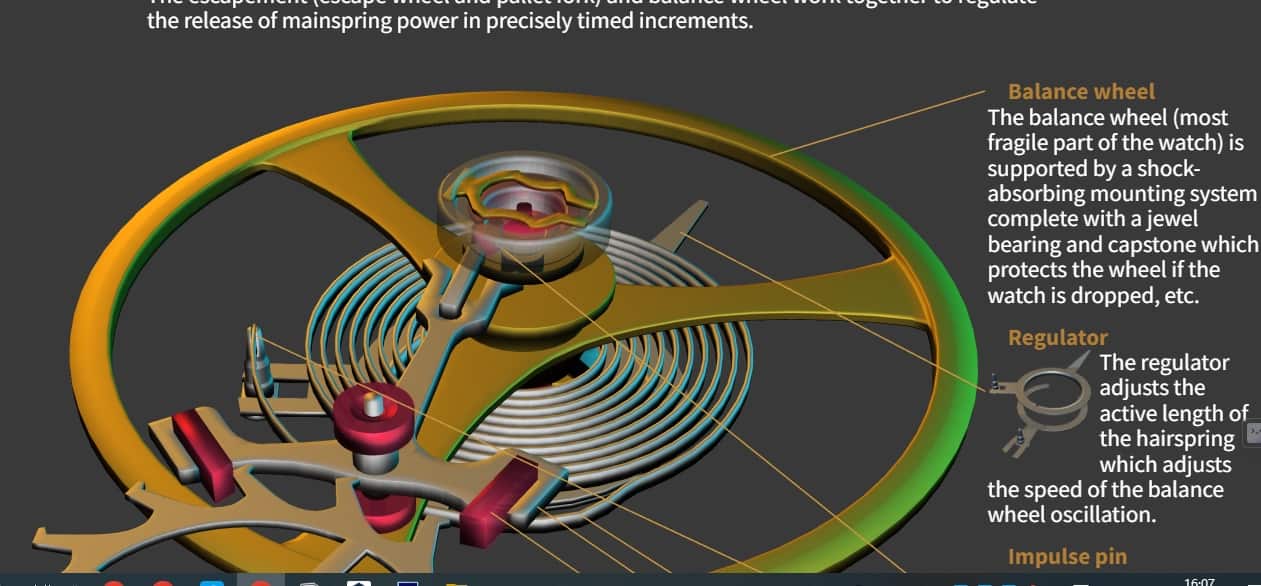

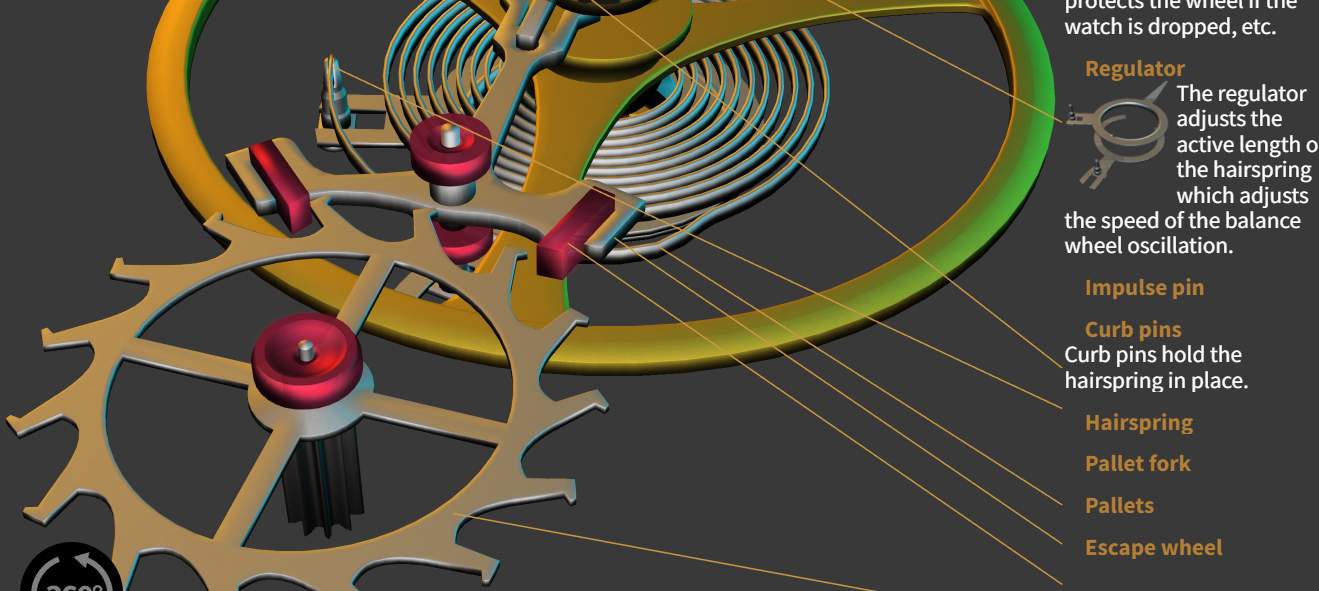

Bevegelse: Jewels are typically used in the movement of a watch, including the bearings of the balance wheel, escapement wheel, and other moving parts. These jewels help reduce friction between mechanical components, enhancing the accuracy and stability of the watch.

Bezel and Dial: Some jewelry watches may also feature gemstones set in the bezel and dial, such as diamonds, sapphires, to enhance the decorative and luxurious aspects of the watch.

Indicators: In some jewelry watches, indicators such as hands and hour markers may also be decorated with gemstones to add quality and unique charm to the watch.

Overall, a jewelry watch with 17 jewels incorporates gemstones in multiple areas, not only enhancing the functionality and performance of the watch but also adding beauty and luxury to the timepiece.

Most jeweled watches typically have around 17 jewels, which are primarily used in the following parts of the movement:

- Balance wheel bearings: Jewels are often used to support the balance wheel, reducing friction and ensuring smooth operation.

balance wheel(picture from https://animagraffs.com/mechanical-watch/) - Escape wheel bearings: Similarly, jewels are used to support the escape wheel, aiding in controlling the watch’s rhythm and accuracy.

- escape wheel.

- Other moving parts: Apart from the balance wheel and escape wheel, jewels may also be utilized to support other critical moving parts within the movement, such as the pallet fork, hairspring, etc.

This post has clear told what’s the mechanical watches’s movement parts: https://animagraffs.com/mechanical-watch/

What does 17 jewels mean? What does 25 jewels on a watch mean?

17 jewels and 25 jewels on a watch refer to the number of synthetic rubies or sapphires used as bearings within the watch movement. This indicates the number of points where the moving parts of the watch, such as gears and pivots, come into contact with the jewels to reduce friction and improve the overall performance and durability of the movement.

So, a watch with 17 jewels means it has 17 synthetic rubies or sapphires serving as bearings, and similarly, a watch with 25 jewels means it has 25 synthetic rubies or sapphires serving as bearings.

Do quartz watches have jewels?

In fact, quartz watches, like mechanical watches, also have moving parts. However, not all quartz watches use jewels in their movements. Before the 1970s, when the Seiko Astron was introduced and launched battery-powered (quartz) watches, all watches were mechanical, and approximately five to seven jewels were used in the movement of a watch.

Quartz MovementYes, quartz watches typically also utilize jewels. Although the movement of a quartz watch is driven by a quartz crystal rather than a traditional mechanical movement, jewels still play an important role in the movement of quartz watches. Jewels are commonly used to support the gear axes and other moving parts of quartz watches to reduce friction and improve the accuracy and durability of the watch.

While the number of jewels required for quartz watches is typically less than traditional mechanical watches, they are still a crucial component for the performance and reliability of quartz watches.

Konklusjon

In summary, diamonds in watch movements contribute not only to aesthetic appeal but also to functionality and performance. While excessive diamonds may lead to drawbacks like increased weight, a balanced use of diamonds can enhance elegance without compromising functionality. It’s essential to consider factors like diamond quality, craftsmanship, and personal lifestyle when choosing a diamond watch.

Alternative materials like synthetic rubies, sapphires, ceramics, stainless steel, and titanium also play significant roles in enhancing watch movements, offering unique benefits in durability and aesthetics. Whether adorned with diamonds or crafted with alternative materials, the key is to strike a balance between functionality, aesthetics, and personal taste. Ultimately, the choice should resonate with individual preferences while ensuring optimal performance and enduring beauty.