O relógio terá muitas cores, então como são feitas as cores nele? Está pintado? Vamos dar uma olhada.

A cor da caixa do relógio é geralmente galvanizada, dividida em galvanoplastia (PVD) e revestimento de água, galvanoplastia (PVD) é de melhor qualidade e pode ser mantida por muito tempo, o revestimento de água é de baixa qualidade e não pode durar.

Vamos ver mais da coloração do relógio.

Qual é o revestimento colorido da indústria de relógios?

Para os não iniciados, você não saberá o que é PVD e o que é IP. O revestimento IP é o método de revestimento mais usado em um relógio

Chapeamento IP é a abreviação de Ion Plating, é uma das categorias de deposição física de vapor (PVD),

O revestimento PVD tem 3 tipos de revestimento: revestimento de ferro (IP), deposição de vapor a vácuo, revestimento por pulverização catódica.

Quantos métodos de revestimento existem na indústria de relógios?

Por que algumas pessoas usam relógios que não perdem a cor durante vários anos, enquanto outras começam a perder a cor depois de alguns meses?

Existem apenas 2 métodos na indústria de relógios, que são o revestimento com água e o revestimento a vácuo (PVD).

O revestimento a água é normalmente usado em relógios baratos, e o revestimento a vácuo (PVD), especialmente o revestimento IP, está sendo usado em marcas de relógios de média alta qualidade.

O que é revestimento de água?

O revestimento com água também é um revestimento aquoso, é o método de revestimento eletrônico tradicional e normal.

Os relógios banhados a água geralmente não são resistentes ao desgaste e são propensos ao desbotamento e à oxidação.

Relógios banhados a água, geralmente você não consegue ver, só com muito tempo para saber se é um revestimento ruim。

Revestimento de água Princípio de funcionamento:

Transforme os produtos químicos de cátions metálicos de revestimento em uma solução aquosa, use o princípio eletrolítico em uma solução contendo cátions metálicos de revestimento para produtos de aço inoxidável revestidos com uma camada fina;

porque o revestimento em solução, também chamado de revestimento com água.

De acordo com as diferentes necessidades dos clientes, use especial “revestimento de água” A solução pode ser usada, e as peças banhadas podem ser acabadas em um curto espaço de tempo (por exemplo, chapeamento de prata, apenas 30 segundos) colocando-as na solução de chapeamento de água em temperatura ambiente (15-40 ℃) e agitando levemente.

Materiais de revestimento comuns usados: cobre, níquel, cromo, zinco, etc.

Recursos com revestimento de água:

- Não há necessidade de fonte de calor, o trabalho de galvanização é realizado a uma temperatura ambiente de 15-40°C

- O princípio não é cobrir, mas fazer a combinação do revestimento e do material de revestimento para formar uma liga, e sua resistência combinada aumenta bastante

- A aparência e a resistência ao desgaste do revestimento de água são melhores

O que é revestimento a vácuo (PVD)

Chapeamento a vácuo, também chamado de PVD (Deposição Física de Vapor)

Termos profissionais de fábrica: Normalmente usamos PVD ou revestimento a vácuo como linguagem de comunicação.

O revestimento a vácuo (PVD) inclui principalmente o revestimento de ferro a vácuo (IP), deposição de vapor a vácuo, revestimento por pulverização catódica e outros métodos de revestimento.

(Não vou mencionar outros revestimentos aqui)

Revestimento iônico a vácuo está colocando o produto em um recipiente a vácuo, também Ip Plating

Usando tecnologia de descarga de arco de baixa tensão e alta corrente, usando descarga de gás para evaporar o material alvo e ionizar o material evaporado, e sob a ação do campo elétrico, o material evaporado ou seus produtos de reação são depositados na peça de trabalho.

também conhecido como revestimento PVD.

Deposição de vapor a vácuo é um método de aquecimento de metais sob condições de alto vácuo, fazendo com que derretam, evaporem e formem uma película metálica na superfície do plástico após o resfriamento. Os materiais comuns são metais de baixo ponto de fusão, como o alumínio.

Revestimento por pulverização catódica a vácuo é a deposição de vários filmes metálicos e não metálicos na superfície do objeto por pulverização catódica sob condições de vácuo, o que resulta em um revestimento superficial muito fino com excelentes vantagens de boa adesão e retenção de cor duradoura. Ainda assim, também é mais caro, pode ser operado com menos tipos de metais e geralmente é usado como revestimento funcional para produtos de qualidade superior.

Entre esses três, o revestimento de ferro a vácuo tem o alcance mais amplo, a deposição de vapor a vácuo e o revestimento por pulverização catódica a vácuo tem o menor alcance, então a pulverização catódica com magnetron a vácuo tem o mesmo significado com o revestimento iônico a vácuo?

–Não, os dois não são iguais. O revestimento iônico a vácuo combina evaporação a vácuo e pulverização catódica a vácuo.

Aplicação de revestimento a vácuo (PVD)

O revestimento a vácuo tem uma ampla gama de aplicações e é mais caro do que o revestimento com água devido ao seu processo complexo e aos altos requisitos ambientais e de equipamento.

Então nos próximos assuntos falaremos apenas do revestimento PVD.

Qual é a diferença entre PVD, IP e Water Plating?

Chapeamento IP —- Revestimento de íons a vácuo

Revestimento PVD —- Deposição Física de Vapor

Lembrar, IP é um dos revestimentos PVD, quando dizemos com fornecedor de revestimento, dizemos PVD ou revestimento IP, eles saberão que é revestimento IP.

E qual é a diferença entre PVD & Revestimento de água?

Comparação de revestimento de água & PVD:

- O PVD é feito em um forno de alto vácuo, enquanto o revestimento aquoso é feito em solução aquosa.

- O processo de galvanização a vácuo é complexo e requer elevados requisitos ambientais e de equipamento, enquanto o processo de galvanização com água é relativamente simples.

- A espessura do revestimento com água pode ser mais espessa, enquanto a espessura do revestimento a vácuo não é tão alta quanto o revestimento com água

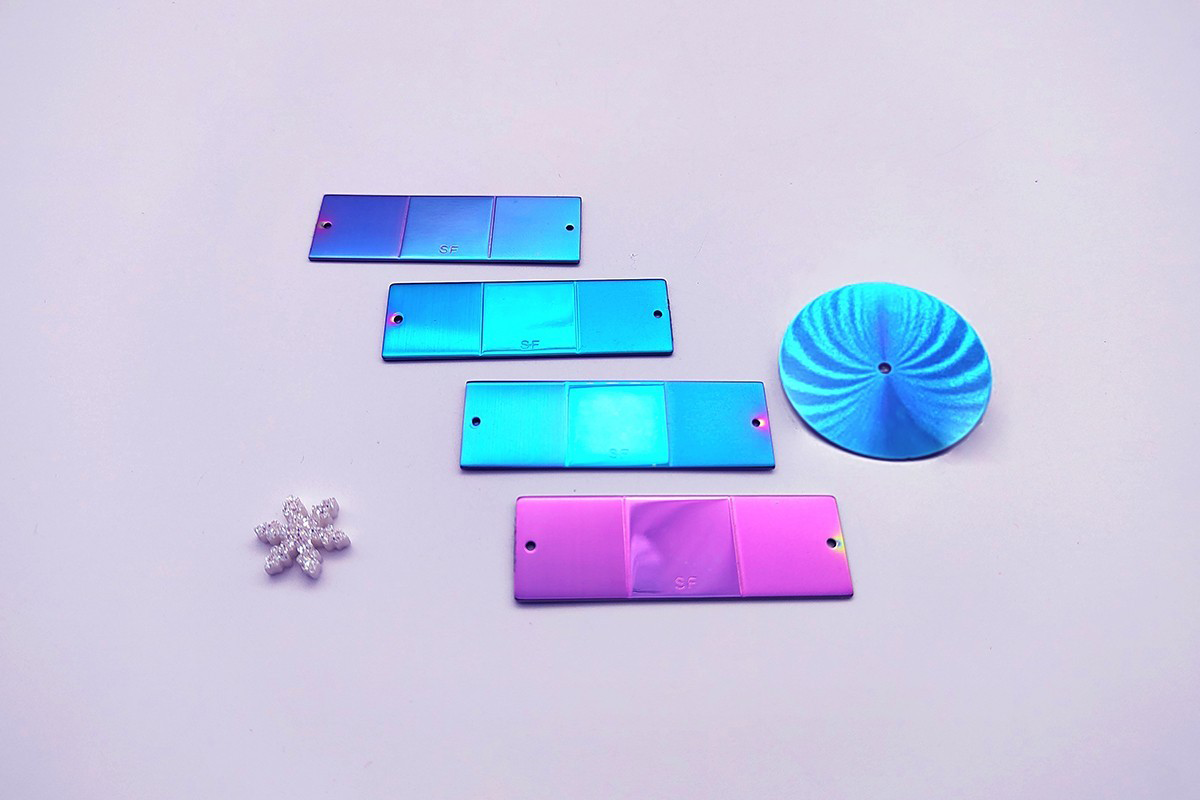

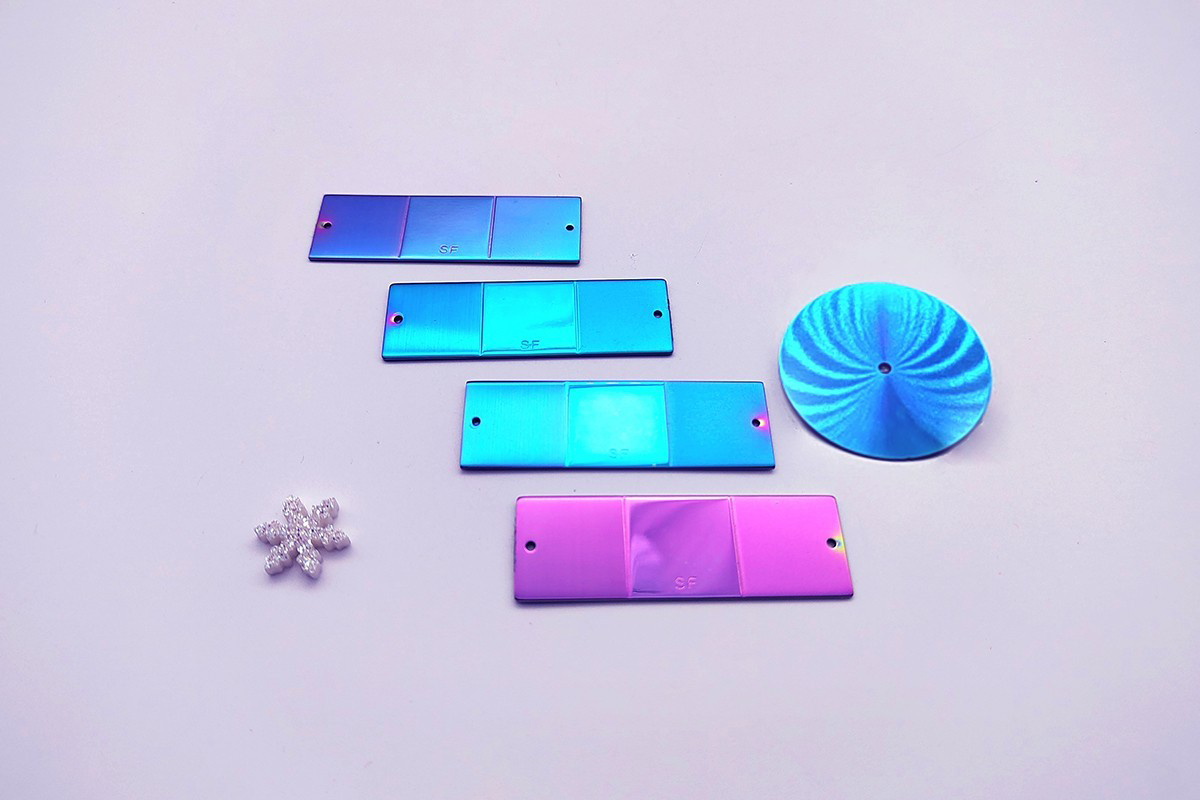

- A cor do revestimento a vácuo é mais rica e brilhante do que a do revestimento com água, e é mais fácil ajustar a cor do revestimento a vácuo do que o revestimento com água.

- A cor do revestimento a vácuo é duradoura e não é fácil de corroer e oxidar, enquanto a dureza do revestimento com água é um pouco melhor, mas é fácil de amarelar, não é resistente à corrosão e não é resistente ao desgaste.

- A cor do revestimento a vácuo só mudará de cor e não cairá, enquanto a cor do revestimento com água cairá

- O revestimento com água é um processo tradicional, e o material de revestimento geral é o cromo hexavalente, que é ecologicamente correto e poluente, enquanto o revestimento a vácuo é de baixo custo, não poluente e altamente eficiente

- O revestimento a vácuo é mais barato que o revestimento com água

- A camada de revestimento iônico a vácuo tem organização densa e sem furos. Sem bolhas e espessura uniforme. Peças como roscas também podem ser revestidas. Como o método de processo também pode reparar pequenas rachaduras e marcas na superfície da peça, ele pode efetivamente melhorar a qualidade da superfície e as propriedades físicas e mecânicas.

Contras e prós do revestimento de água

Contras:

A cor do aço inoxidável com revestimento de água preta é mais vívida; se você escolher o titânio preto com revestimento de água em aço inoxidável 304, a cor é um pouco azul. A vantagem é que o preço é barato.

Prós:

A desvantagem é que a cor é monótona, polui o meio ambiente, a cor não é suficientemente pura e estável; no final, a cor do revestimento sairá em pedaços grandes.

Contras e prós do revestimento PVD

Contras:

Os produtos fabricados por revestimento a vácuo possuem forte sensação de metal e alto brilho. Comparado com outros métodos de revestimento, o custo é baixo e a poluição ao meio ambiente é pequena, por isso é agora amplamente utilizado em diversas indústrias.

Resistência do filme PVD: resistência à corrosão, resistência a ácidos e estabilidade química, no ambiente convencional, seja interno ou externo, o PVD tem desempenho antioxidante, não desbota, não perde brilho e não deixa vestígios.

Sob uso normal, a cor não quebra, não desbota e a sujeira é fácil de limpar. Sob luz solar forte, zonas húmidas salgadas e ambientes urbanos, não descolorem, não oxidam, não caem e rebentam, a cor da camada de película varia, a superfície é fina e lisa, rico brilho metálico, nunca desbota. Alto grau de resistência ao desgaste, resistência a arranhões, não é fácil de arranhar;

Após ser processada pelo revestimento PVD, a superfície do produto pode ter revestimento de alta dureza, e a força de ligação entre o revestimento e a superfície do aço inoxidável é maior e não descasca;

a resistência à abrasão e corrosão é maior, e também é estável e resistente à oxidação em alta temperatura; o processo de galvanização não produz substâncias tóxicas ou poluentes como o galvanização com água.

Prós:

A desvantagem é que é caro

Assistir ao processo de galvanização

O processo de revestimento com água é:

- Desengordurante (desengorduramento),

- rugosidade,

- Neutralização e redução ou imersão,

- Ativação,

- Descolando,

- Chapeamento químico,

- Galvanoplastia de níquel e galvanoplastia de cromo.

A adesão do revestimento com água é melhor do que o revestimento a vácuo (PVD).

A cor do revestimento de água é monótona, geralmente apenas alguns tipos de prata brilhante e sub-prata, e não pode fazer as sete cores coloridas, como prata flash, azul mágico, crack, prata lágrima, etc. Mas o revestimento a vácuo pode fazer cores de 7 cores.

Processo de PVD

O processo PVD é:

- Inspeção de material recebido

- Limpando e pendurando o material

- Limpeza

- Coloque os produtos na assadeira

- Coloque o produto no forno

- Revestimento a vácuo

- Retire do forno

- Tire da prateleira

- Inspeção completa

- Envio

Notas especiais de produção:

- O tempo de produção precisa de pelo menos 24 horas. Depende também do cronograma de produção da fábrica.

- O processo de limpeza é fundamental e o tempo de processamento no forno não pode ser menor.

- Antes do chapeamento, o processo de limpeza consiste em usar soda cáustica para remover o óleo e desengordurar

- Para usar qual soda cáustica, depende do óleo na superfície das peças chapeadas, às vezes é necessário usar soda cáustica forte para limpar

Mais pergunta:

P: O revestimento a vácuo e o revestimento são iguais?

Não, eles não são iguais, o revestimento colorido será mais espesso do que o revestimento a vácuo, e o revestimento é usado apenas no mostrador do relógio ou na fivela da pulseira. O revestimento colorido também é usado para algumas cores especiais que o PVD não consegue alcançar, então você usa óleo em spray. O revestimento de óleo é menos utilizado em caixas de relógios.

P: Como está a espessura do revestimento da cor do relógio?

A espessura do revestimento de água é geralmente 30um,

A espessura da camada de revestimento a vácuo é geralmente de 0,1um – 5um, também pode ser feito de acordo com as necessidades do cliente da fábrica.

a camada de revestimento a vácuo pode durar muito tempo e tem excelente sensação de desgaste e resistência à corrosão, ideal para joias, relógios e acessórios

P: Cor do chapeamento do relógio?

A cor pode ser ouro claro, ouro, ouro rosa, café, cinza, preto, marrom, bronze, etc.

Saiba mais no artigo abaixo

Conhecimento básico sobre caixa e parte traseira do relógio de pulso

P: Relógios com revestimento iônico (relógios PVD) Durabilidade 、 a cor do PVD cairá?

O revestimento PVD não cairá pedaço por pedaço como o revestimento com água, mas a cor desaparecerá lentamente com o passar do tempo, ainda não vimos nenhuma perda grave de cor, depende principalmente do grau de manutenção, muita transpiração e contato com produtos químicos irão afetá-lo, se a cor do PVD desbotar, você precisa usar uma solução química para retirar o revestimento residual e depois recolocá-lo.

P: A cor PVD Gold cai facilmente?

Entre todas as cores de revestimento, o dourado é a cor mais difícil de manter.

Embora o revestimento de ouro seja uma camada de filme composto, para obter o brilho do ouro, a camada superficial do filme é a camada de ouro puro, porque as características do ouro são muito macias, então o ouro será mais fácil do que outro revestimento a vácuo para arranhar lesões na inserção.

Pensamento final

O revestimento do relógio é um processo muito óbvio para identificar um relógio bom ou ruim. Relógios de baixa qualidade geralmente usam revestimento de água e, depois de alguns meses, os relógios ficam descoloridos, o que é muito sério. Ao se comunicar com seu fornecedor de relógios, lembre-se de enfatizar o uso de revestimento PVD ou IP!