Just Stones! Makes the Rolex’s Trendsetting Blue and Green Dials

“All things that are beautiful with color, such as flowers and leaves, or the blue of the sky and the glory of sunset, are fleeting and ever-changing. Only the luster and color of precious stones have remained unchanged from thousands of years ago until now. Thousands of years later, they will be the same”

-[The Curious Lore of Precious Stone]

George F. Kunz (Gemologist and mineralogist, year 1856~1932)

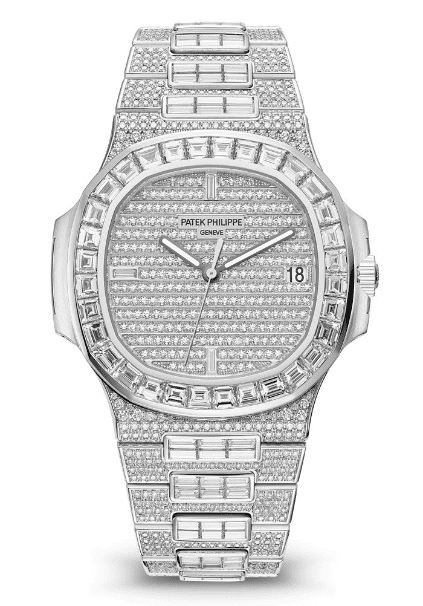

The use of gemstones is not limited to jewelry; they are also common in watchmaking. Most gemstones are known for their durability, and their rich colors and luster enhance the aesthetics of timepieces.

They are set into watch cases and used as decorations on watch dials. Similar to Pantone announcing the color of the year, in recent years, there has been a trend in the watch industry where different colors dominate watch dials at different times.

Brands achieve color expression through techniques such as paintin and enamel, and using gemstones of various materials to craft dials is also a popular method.

For wristwatches, what defines beauty?

We commonly consider factors such as case design, dial layout, transparent case backs, and intricate functionalities—all within the confines of a small space, where beauty lies in the details.

The dial, often compared to a “facial expression” for watches, is undoubtedly influenced by its color. As mentioned, when gemstones are crafted into watch dials, the emphasis tends to lean towards considerations of “color coordination.” Therefore, compared to the intrinsic value of the gemstone itself, its color plays a crucial role in expressing the overall aesthetic appeal of the watch and significantly impacts its value.

In the pursuit of enhancing the visual allure of this “face,” brands invest effort into selecting gemstones of appropriate colors.

This post utilizing various types of precious gemstones, and the following is an introduction to some commonly used gemstones in the creation of watch dials.

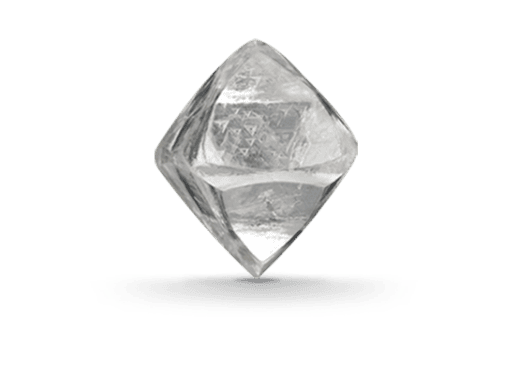

01 Diamond

Diamond is the only gemstone composed of a single element—carbon atoms, with a carbon content as high as 99.95%. The remaining 0.05% consists of trace elements not belonging to its basic chemical structure. Most diamonds formed during the ancient era, over a billion years ago, and they only crystallized under high temperature and pressure conditions approximately 100 miles beneath the Earth’s surface.

How do we evaluate the quality of a colorless diamond? It’s based on the 4Cs: Carat (weight), Color, Clarity, and Cut. According to these criteria, a good diamond is one that is larger, more colorless, clearer, and well-cut. Additionally, there are a few precious colored diamonds with extremely high value.

Diamonds have a long history, with records of diamond trading dating back to as early as 800 BC in India. Today, diamonds are widely prevalent globally. South Africa and Australia are major diamond-producing regions.

Diamonds possess a dazzling brilliance unmatched by other gemstones. They are not only favored in jewelry but are also frequently featured in watches. As the hardest gemstone in the world, diamonds are often presented in watches as part of the dial, showcasing their sparkle through intricate settings.

02 Lapis Lazuli

Mohs Hardness: 5-5.5

Lapis Lazuli is a rare metamorphic rock primarily composed of a mineral with sodium, aluminum, silicon, sulfur, chloride, and hydroxide, along with varying amounts of pyrite and white calcite. It is a semi-transparent to opaque gemstone with a waxy to glassy luster.

The color of Lapis Lazuli varies from slightly greenish blue to violet-blue, and high-quality lapis lazuli is characterized by a uniform, highly saturated blue with minimal golden flecks.

As early as 3100 BCE, there are records of lapis lazuli being mined, making it possibly the earliest used blue gemstone by humans. In ancient civilizations, including Mesopotamia, Egypt, China, Greece, and Rome, lapis lazuli was considered a precious gem. Before the early 19th century, it was ground into powder and used as a deep blue pigment. During the Renaissance, artists used it to create a high-quality blue pigment known as “Ultramarine.”

Lapis Lazuli has a long history of mining in Afghanistan and remains a primary source to this day. Other major producing areas include Chile and Russia. Lapis Lazuli has consistently been a favored material for watch dials in luxury timepieces

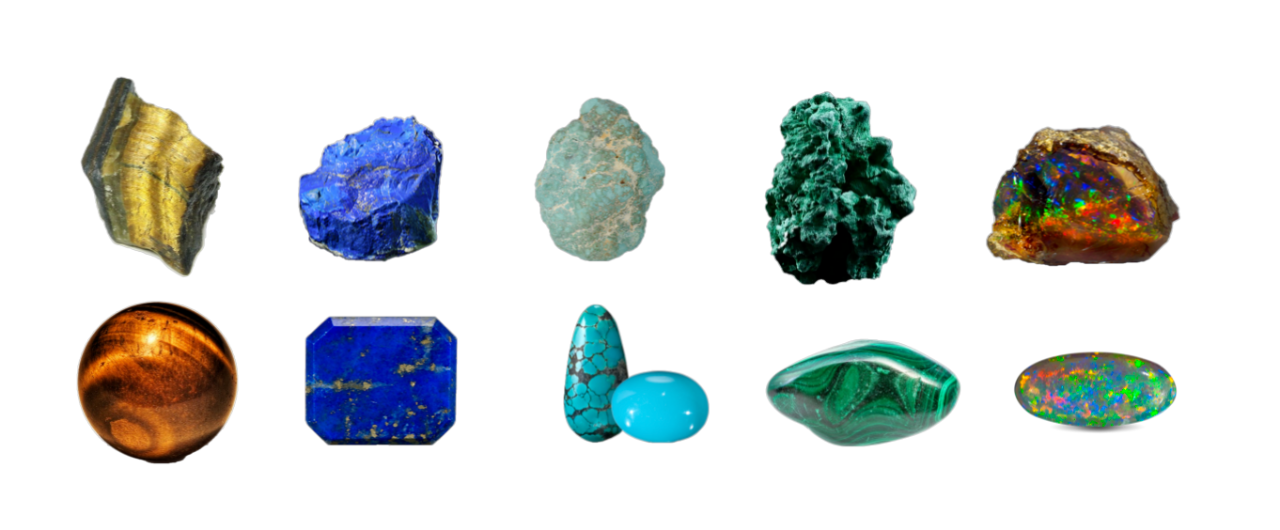

03 Tiger’s Eye

Mohs Hardness: 6.5-7

Tiger’s Eye is a semi-precious variety of quartz known for its chatoyancy—a phenomenon where a bright band of light, resembling the long, narrow eye of a cat, appears on the gemstone’s curved surface. It is named for its resemblance to the sharp eyes of a tiger.

Images from the Internet

Tiger’s Eye forms during the initial stages of the alteration of crocidolite fibers, first turning into iron oxide and later replaced by silica. The gemstone is typically opaque and ranges in color from rich yellow to brown. A high-quality Tiger’s Eye should exhibit flawless surfaces, with a well-defined and bright cat’s eye effect positioned centrally.

Tiger’s Eye has historical mentions dating back to ancient Roman and Egyptian times, where it was associated with sun gods and victory. The primary sources of Tiger’s Eye include South Africa, Brazil, and China.

After undergoing cabochon cutting, Tiger’s Eye displays excellent luster, and its attractiveness is further enhanced by different reflections when viewed from various angles.

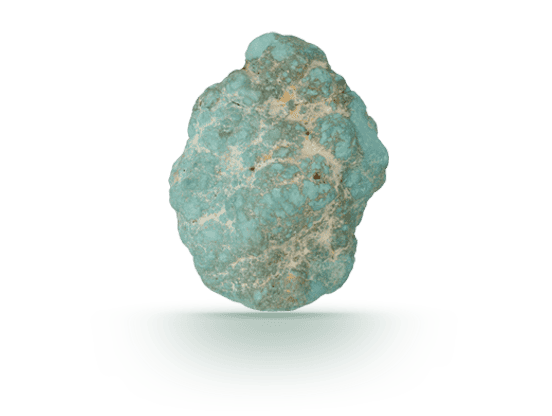

04 Turquoise

Mohs Hardness: 5-6

Turquoise is a gemstone formed in crystalline structures near shallow water in arid and barren regions. It is a semi-translucent to opaque gem, commonly appearing in an opaque form with stripes, spots, or iron-like vein patterns. The finest quality turquoise exhibits a unique and intense blue hue, often described as “robin’s egg blue,” “sky blue,” or “Persian blue.”

Turquoise has a long history and holds the distinction of being the first gemstone to be mined and replicated. As early as 4000 BCE, beads made of turquoise were discovered in burial sites in ancient Egyptian tombs.

Iran and the United States are currently significant sources of high-quality turquoise, with China being the largest global producer. Additionally, Mexico, Australia, Chile, Russia, Turkey, and other regions also contribute to turquoise production.

05 Chrysocolla(also named: Turquoise)

Mohs Hardness: 3.5-4.5

Above mentioned Turquoise is not the same stone with Chrysocolla, but name might be the same, Chrysocolla is a copper-bearing mineral known for its turquoise-green color, and high-quality specimens often feature blocky formations with greenish bands. It is frequently confused with turquoise due to similar appearance and color. While turquoise has a blue base, turquoise is green and can range from transparent to semi-translucent.

Chrysocolla/Turquoise can be considered one of the most crucial minerals in human history. It is believed that as early as 4000 BCE, people discovered that heating turquoise could produce natural copper.

this might have been the first instance of humans smelting metal from ore, sparking exploration into metallic ores and advancing the development of metallurgy. In ancient Egypt around 3000 BCE, turquoise was recognized and used as an amulet, jewelry, and eyeshadow.

06 Jadeite

Mohs Hardness: 7

Chalcedony is formed when low-temperature, silica-rich solutions permeate existing rocks, especially volcanic rocks, in cavities and fractures. It is one of the earliest gemstone materials in the world. Pure chalcedony is white, but it takes on rich colors when it contains various trace elements or mineral inclusions.

Many varieties of chalcedony have specific names, such as agate, chrysoprase, bloodstone, green chalcedony, red chalcedony, blue chalcedony, and carnelian, with green chalcedony being particularly valuable.

To further differentiate, agate is the most representative variety of chalcedony, and if it has a clear banded structure, it is called agate. If it lacks a banded structure, it is considered chalcedony. Agate is characterized by concentric color banding in most specimens, displaying diverse colors due to different impurities, while chalcedony lacks banded textures and exhibits a uniform color.

Chalcedony artifacts date back to the Stone Age, with adornments found from as early as 20,000 to 160,000 years ago. By 3000 BCE, ancient Egyptians were already using agate, red chalcedony, and green chalcedony as decorative items.

Chalcedony is found worldwide, with significant deposits in Brazil, Uruguay, and India, yielding various types of chalcedony. Other regions also produce different varieties of chalcedony, such as China, which is a major producer of bloodstone. Chalcedony and chrysoprase are commonly used in watch dials.

07 Euclase

Mohs Hardness: 5.5-6.5

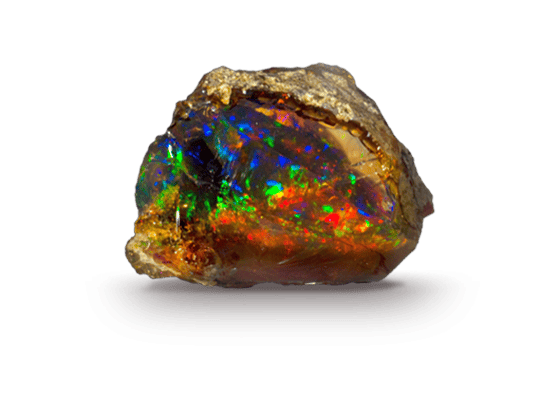

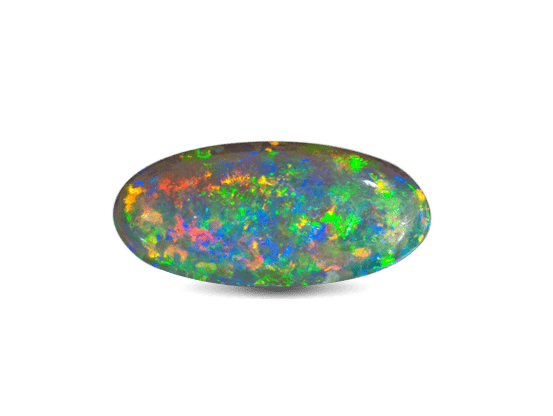

Euclase forms as silica seeps into rocks beneath the ground through rainwater. As the water evaporates, silica deposits in the form of small spheres and binds with more silicon and water, creating “euclase.”

What makes euclase particularly enchanting is its iridescence. When the gem is moved, various colors of shimmering reflections can be observed. This iridescence is only formed when the silica spheres are of the appropriate size and arranged in a regular pattern. The more orderly the arrangement, the larger the iridescent area, and the more pronounced the color changes. This iridescence is considered the soul and value of euclase. “Precious euclase” is defined by having the iridescence, with red iridescence being the most valuable.

According to records, the oldest euclase mining area is in Hungary, with mining dating back to the 14th century, and it continues to be a source of euclase today. Australia is the largest producer of euclase, and Mexico and South Africa are also major producing regions.

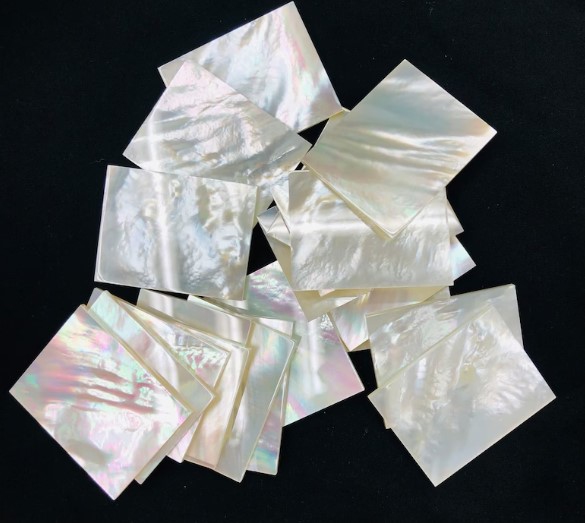

08 Mother of Pearl (another name: Nacre)

Mohs Hardness: 2.5-4

Mother of Pearl refers to the inner lining of certain mollusk shells that can naturally produce pearls. These mollusks typically inhabit shallow waters and are found in coral reefs and seabeds in the Pacific, Atlantic, and Indian Oceans. Over the extended period during which pearls form, the inner lining of the Mother of Pearl is coated with nacre, lending it color and making it a beautiful and sought-after material.

Compared to pearls, Mother of Pearl is more durable and resilient. Since the 13th century, it has been cherished by European nobility as a material for decorative arts. Mother of Pearl was used to adorn furniture, create jewelry boxes, and even used in the crafting of knife handles, becoming an essential part of life during that era. Mother of Pearl is a common material in watch dials.

Mother of Pearl comes in two varieties: industrial-grade and gem-grade, with the latter being rarer. The material used on watch dials is of gem-grade quality. Each natural gemstone undergoes meticulous processes such as sorting, splitting, cutting, grinding, polishing, finishing, drilling, carving, and setting before it reaches its final form as a captivating watch dial.

09 Meteorite

Mohs Hardness: around 4.5 to 5.5

A meteorite is a fragment of a celestial body, such as a comet, asteroid, or meteoroid, that survives its passage through the Earth’s atmosphere and lands on the Earth’s surface. These fragments can range in size from tiny particles to large masses weighing several tons. Meteorites provide valuable scientific information about the early solar system and beyond.

There are three main types of meteorites based on their composition:

- Stony Meteorites (Chondrites): These are the most common type and consist largely of silicate minerals. Chondrites often contain small, spherical structures called chondrules, which are thought to be among the earliest solid materials formed in the solar system.

- Iron Meteorites: Comprising mostly metallic iron-nickel alloy, these meteorites are dense and often have a distinctive, polished surface called a Widmanstätten pattern. This pattern is the result of the slow cooling of metal in space over millions of years.

meteorite dial-image from internet - Stony-Iron Meteorites: These meteorites contain a mix of silicate minerals and metallic iron-nickel alloy. They are relatively rare and are divided into two main groups: pallasites, which have olivine crystals embedded in a metal matrix, and mesosiderites, which have a complex mixture of metal and silicate minerals.

Meteorites can be classified further based on their fall characteristics, composition, and structure. They provide insights into the early solar system’s conditions and the processes that led to the formation of planets and other celestial bodies. Scientists study meteorites to learn more about the origins and evolution of our solar system.

Pensamento final:

If you are familiar with jewelry, you can see that all these gemstones are also used in jewelry, such as earrings and necklaces, bracelets, and rings, Different gemstones are chosen for their unique colors, properties, and aesthetics, allowing jewelry designers to create diverse and exquisite pieces.

As a gift from nature, each natural gemstone is unique, showcasing the beauty of nature in various forms. Have you bought any watches with watch dials made from natural gemstones?

Source:

Lapis Lazuli: https://en.wikipedia.org/wiki/Lapis_lazuli

Tiger’s Eye: https://en.wikipedia.org/wiki/Tiger%27s_eye

Turquoise: https://en.wikipedia.org/wiki/Turquoise

Chrysocolla: https://en.wikipedia.org/wiki/Chrysocolla

Chalcedony: https://en.wikipedia.org/wiki/Chalcedony

Meteorite: https://en.wikipedia.org/wiki/Meteorite